A Mackay based company has developed a smart innovation to minimise conveyor roller failure and potential belt fires.

Conveyor roller failure is the leading cause of belt damage and has been identified as a primary ignition source in underground coal mine fires. Australian owned, Mackay based company, Vayeron®’s Smart-Idler®, provides operators extensive information on the condition of rollers helping mine operators minimise expensive failure events. It reduces the risk of fires, belt tears, excessive noise and tracking problems on rollers

The Smart-Idler® allows personnel to view the status of your conveyor rollers remotely from the comfort and safety of a control room. It reduces exposure to mechanical hazards associated with manual inspection methods, and instantly alerts operators to unsafe temperature rises in the roller bearings, reducing the potential for fires on your conveyor.

The Smart-Idler® allows personnel to view the status of your conveyor rollers remotely from the comfort and safety of a control room. It reduces exposure to mechanical hazards associated with manual inspection methods, and instantly alerts operators to unsafe temperature rises in the roller bearings, reducing the potential for fires on your conveyor.

What is Smart Idler?

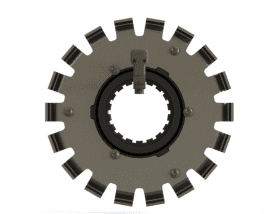

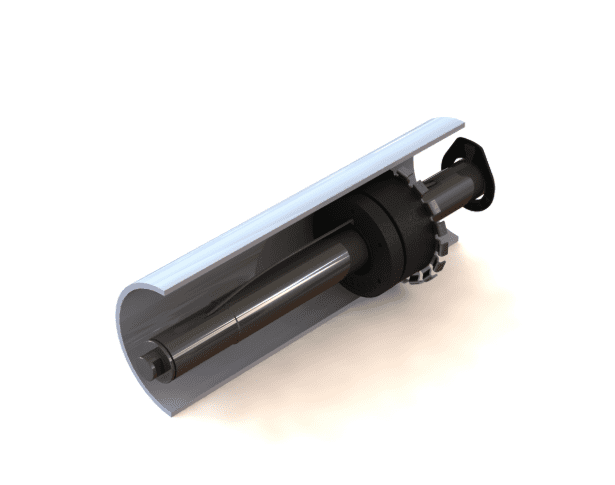

The Smart-Idler® system is an electronic device that is internally installed into the roller during the roller’s manufacturing. It is completely wireless, harvesting power directly from the rotation of rollers and relaying data via a radio network.

According to Vayeron, there is no special wiring required for a conveyor. The Smart-Idler® is a roller sub-component and seamlessly integrates with the roller of your choice. Simply drop in a roller embedded with the Smart-Idler®, install a gateway module and you’re off and rolling!

Real-time roller data and alerts are then sent straight to control rooms via a user-friendly SCADA or Cloud based GUI system.

Feature of the system include:

- Vibration sensing

- Acoustic sensing

- Shell-wear detection

- Temperature sensing

- Wireless technology

- RFID asset tagging for advance data collection

- RPM sensing

- No batteries required

Based in Mackay, Australia, Vayeron® is an OEM technology company focused on providing intelligent solutions to industrial productivity challenges, particularly in the mining sector. Vayeron® is a pioneer in the field of applying innovative ‘Industrial Internet of Things (IIoT)’ technology for vibration analysis and condition monitoring of bearings and shafts.

Read more Mining Safety News

Add Comment