Cutting-edge Technology made simple.

Advanced Photonics

Fight Fire with Fibre

Fire Protection Systems

Avoid a fire with early detection using fiber optic distributed temperature sensing.

Commercial Fire Detection Systems

Harness the power of linear heat detection with cutting edge fire protection technologies.

Welcome to

Advanced Photonics Australia

Advanced Photonics Australia’s fiber optic distributed temperature sensing solutions include Distributed Temperature Sensing (DTS) And Distributed Acoustic Sensing (DAS) for a wide range of heavy industry applications. We have adopted the latest proven technology in the field of Photonics to engineer industry leading commercial, industrial and mine safety technologies for even the most onerous operating environments. Our fire monitoring systems provide continuous condition monitoring of key assets. This protects the safety of staff and allows for a predictive asset management approach to be established which minimises unplanned outages and avoids unnecessary maintenance of equipment.

Downloads

Want to know more about the technology?

Download our company brochure, white papers and product information here.

Improve Your Safety

Disaster Prevention

Enquire Now

Please select from the following options:

Increasing Availability

Through these System Configurations

DTS system without Redundancy

Sensor cable as open line, no sensor cable redundancy, no detector redundancy.EN 54-22: maximum area protected by sensor cable = 1600m2AS1670.1: maximum zone area = 2000m2

DTS System with Cable Redundancy

Sensor cable as loop, detector with 2 channels, no detector redundancy.

EN 54-22: maximum are protected with sensor cable as loop = 10000m2

DTS System for Full Redundancy

Sensor cables as 2 loops, two DTS detectors, full redundancy – highest reliability.

EN 54-22: maximum area protected by sensor cable as loop between two detectors = 10000m2 for each sensor cable loop.

Testimonials

Keeping you informed

Recent Articles

The challenges of traditional fire detection methods, and how fibre optics is revolutionising safety

The consequences of a fire outbreak in high-risk working environments can be catastrophic. These events can jeopardise the safety of personnel and the integrity of critical infrastructure and operations on-site.Traditionally, fire detection in industrial settings has relied heavily on a variety of outdated and manual methods. These methods often include manual inspections and automated systems that utilise thermal sensors, smoke detectors, thermal cameras, or copper linear heat detectors.Whilst these methods have served their purpose to an extent, they come with inherent limitations that compromise their effectiveness. Particularly in environments characterised by harsh conditions (underground mining) and vast expanses (industrial solar farms).In this blog, we delve into the challenges associated with traditional fire detection and explore the fibre optic benefits in environments such as underground mines, solar farms, and data centres.

Understanding the limitations of traditional fire detection methods

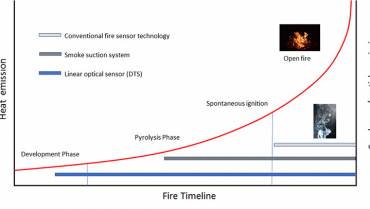

The shortcomings of traditional fire detection systems pose significant challenges in effectively identifying and preventing fires in industrial environments. Traditional methods often lack the reliability and precision required to detect early-stage fires or heat detection in smouldering phases. False alarms, whether triggered by environmental factors or technical malfunctions, can interrupt operation and desensitise personnel and lead to safety complacency on site.The reactive nature of many traditional methods means that by the time a fire is detected, it may have already caused substantial damage to infrastructure and equipment or posed a threat to personnel safety.Here are just a couple of examples of traditional fire detection methods that can leave you exposed to fire risk.Manual Fire Inspections

Manual inspections require personnel to physically inspect and patrol the premises with the intention of reviewing infrastructure for signs of overheating or fire. While manual inspections allow for direct observation and assessment of potential hazards, this method presents risk.In large-scale industrial settings including underground mining and utility tunnels, expansive solar farms and data centres, manual inspection can be labour-intensive, time-consuming, and subject to human error.Conducting thorough inspection across vast areas naturally presents logistical challenges, especially in environments that may have restricted or hazardous conditions.Underground mines are particularly tricky, due to confined spaces, and areas with high levels of dust or debris. These environments provide multiple roadblocks for safety personnel on-site, when trying to ensure comprehensive coverage through manual inspections.Basic Automated Fire Detection Systems

Automated fire detection systems (thermal sensors and smoke detectors) offer a more proactive approach to fire prevention. Utilising sensors or detectors can assist in monitoring signs of abnormal temperature fluctuations and signs of fire on-site. However, traditional automated systems have limited capabilities, which mean they can still present safety risk.Thermal sensors, for instance, detect temperature changes and are commonly triggered when predefined temperature thresholds are exceeded. In some scenarios on-site, sensors may be confused by hazardous conditions (dust), and struggle to differentiate between harmless variations and genuine fire hazards. Harsher environments can lead to missed detections or even false alarms, which are both costly and unsafe.Similarly, smoke detectors rely on the detection of airborne particulate matter (a mixture of solids and aerosols, small droplets of liquid, or dry solid fragments) in the air. This type of system's reliability is compromised when used in industries such as mining and solar farms.Overcoming the limitations of traditional fire detection methods through fibre optics

Fibre optic innovation plays an essential role in identifying hazards before they escalate into emergencies.The development of fibre optic technologies has sparked a revolution in how key safety personnel approach fire detection and prevention in industrial settings. This approach of fire detection represents a safety-driven shift from traditional methods, offering innovative advantages that redefine fire prevention and risk mitigation.Unlike discrete sensors or manual inspections, our advanced fibre optic detection cabling enables continuous, real-time monitoring of temperature changes.This innovative fire detection solution is facilitated through a 4mm stainless steel-reinforced fibre optic cable, which acts as the sensor.This cable is accredited for fire detection use, with a flame resistance of 750°C for up to 2 hrs. The ability to withstand harsh environments is also supported by the high crush resistance of the stainless-steel cable sheath.Paired with Distributed Temperature Sensing (DTS) technology, there is 24/7 remote temperature monitoring along the entire fibre optic cable.The DTS detector uses a safe, low-power laser (class 1M) to generate measurement pulses in the cable. Data is polled every 10 seconds, with measurement points every 0.5 metres. The coverage capability is also vast, spanning from 1-70km.Some other key fibre optic benefits include:- Design and installation costs are minimal and tailored to each site,

- No calibration is required after commission,

- Costs are reduced on spare parts and repairs, with a 40-year lifespan,

- Certifications from Vds,FMGlobal, UL, and EN54-22, leading to lower insurance premiums,

- Resistant to electromagnetic interference, complying with EMI standards.

Don't settle for outdated fire detection methods. Book your demo and step into the future of fire safety.

Mine Safety: The role fibre-optics play in mitigating fire risks in underground mines

Underground mining is a complex environment where it’s not only crucial to protect people and assets, but to adhere to strict mine safety regulations.The confined nature of the operational environment, risk of noxious fumes, and limited ability to evacuate quickly can all pose a significant risk should a fire occur. Therefore, it is critical to mitigate the risk of fire, and not just manage the fire after ignition.

Potential causes of fire, and related mine safety risks

We've outlined common risks in underground mines to show how our fire protection technologies ensure safer operations in challenging environments.Spontaneous combustion of coal is one of the leading causes of fires in Australian mines. However, many hazards contribute to mine safety risks.Oxidation and spontaneous combustion of coal

When coal merges with oxygen this results in an exothermic reaction that emits heat into the surrounding air. If heat is not regulated and removed from the environment there is a risk of spontaneous combustion. This can then lead to a flaming fire.This reaction is another factor to consider when assessing the importance of adequate ventilation for mine safety. Ventilation systems are broken down into two key components, primary and secondary ventilation. Mining managers need to ensure a clear plan of the ventilation system is kept on site. This should demonstrate what systems are in place for the prevention of coal oxidation combustion.Incorporating our fibre optic heat detection system allows you to identify any issues in ventilation early on. This is achieved by detecting fluctuations in temperature. These readings are detected along the entirety of the underground mine (down to 0.5m lengths), including any shafts on site.Insufficient ventilation

Ventilation is essential when it comes to preventing the build-up of methane gas on-site. It is also of critical importance for the occupational safety of workers. Underground mines often have confined spaces with limited air flow. This presents the opportunity for fumes from machinery and vehicle exhausts to build up.Explosive risk is also increased when drilling is carried out due to the presence of natural gases. These include methane, carbon monoxide, carbon dioxide, sulphur dioxide, and other hydrocarbons. Toxic gasses in underground tunnels make underground mines extremely susceptible to a fire risk.The most common spontaneous mine safety risks are found in coal mines. Ventilation machinery is often used in these environments to regulate the quality of air for workers.In the event of ventilation machinery overheating, this can increase the on-site explosion risk.Improper supervision

Supervision is fundamental when it comes to mine safety. According to a NSW Mine safety report, most recorded incidents were due to work being undertaken unsupervised. You can read more about Safety performance in NSW here.As mining workers are becoming more autonomous and fewer personnel are present on-site, this amplifies the need for reliable technology for 24/7 site monitoring to prevent spontaneous combustion.Mitigating the risk of spontaneous combustion in underground mines

Due to the hazardous environment in mines present (where dirt, dust, humidity and corrosive atmospheres are inevitable), fire monitoring systems and conventional temperature sensor technology don’t always provide the protection needed.Advanced Photonics Australia’s fibre optic distributed temperature sensing (DTS) uses industry-leading technology to reliably and accurately detect changes in temperature onsite – before ignition. This ruggedised system of fibre-optic distributed temperature sensing has the capacity to quickly detect heat build-up to within 0.5 metres of its source.This technology is paramount for underground mine safety, as it provides real-time feedback on both the intensity and location of any temperature peaks. Fibre optics allows you to prevent combustion, suppress fires, and complete early evacuation if required.The cable detects not only convective but also conductive and radiant (infrared) heat. The central DTS unit can interface directly or remotely with existing fire alarm panels and systems. This unit provides real-time and detailed alerts regarding both the location and intensity of the heat source. With this technology you received the advanced warning required for a strategic evacuation and fire suppression response.Heat detection in smouldering phase to prevent fire development

Fire prevention and fire detection are integrated with close monitoring of fire development. Insufficient detection of fires during the smouldering phase can have a detrimental effect on workers onsite.Smouldering combustion is a flameless reaction on a surface, involving movement of heat, mass, and chemical reactions.It is essential to detect a fire in the smouldering phase to allow adequate time to react and rectify the abnormal heat build-up or evacuate the area when appropriate.Early warning of an impending fire is critical to enable action to avoid an irreversible fire event. Smouldering coal takes on average 16 to 24 minutes to erupt into a flame, which could set off a material fire or even an explosion.Our distributed temperature sensing solution will detect smouldering coal ahead of conventional gas or infrared detectors as the cable sensors are not compromised by high airflow. The fibre cable has also been accredited to be flame resistant at 750 degrees Celsius for two hours (IEC 60331).Early detection with fibre optic technology

Traditionally, fire detection in mines, process plants and other industrial environments has been difficult to achieve and inefficient to operate due to the limitations of conventional addressable fire detection systems. This includes the need to be powered across large geographical distances, false positives being constantly triggered by contaminants in harsh environments and the ongoing expense and inconvenience of calibration and maintenance.Advanced Photonics Australia provides a reliable and accurate fire protection system for fire detection in large industrial environments (including coal mines), that solves these problems and sets a new benchmark for fire protection technology.The DTS uses a singular fibre optic cable for rapid and accurate fire detection. This fibre optic cable connects back to the DTS unit, which analyses the data sensed by the cables. The DTS system then provides real-time alerts, pinpointing exactly where there has been a significant temperature change or where a fire has been detected.Due to the multiple forms of temperature measurement (convective and conduction) employed by the system, the precision of the collected data allows you to effectively address the area of concern before the increased risk of explosion arises.As the fibre optic cable is the sensor, no other cabling or field interface devices are required, reducing potential failure points and improving overall safety, especially in hazardous explosive areas.Book a demonstration with our team to see how our fibre-optic technology can safeguard your underground mine from potential fires.

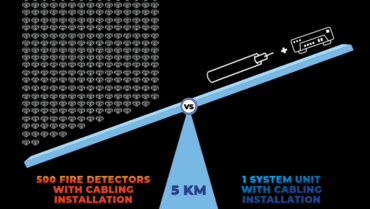

Fibre Optic System 34% cheaper than Conventional Fire Detection Systems

Conventional fire detection systems are onerous in many ways: device intensive, require costly maintenance and time consuming replacements. All these aspects cause a burden for the clients with a high total cost of ownership and a toll on planet Earth with the substantial amount of devices that are discarded every year on e-waste.A recent technology comparison took into consideration the supply and installation of the Conventional Fire Detection Systems and Fibre Optic System on a 5 kilometre range. The results showed that the Fibre system is 34% cheaper than the conventional ones in terms of supply and install. Additional savings are also present on maintenance as the advanced system does not need maintenance after installed and doesn't require numerous devices as one cable does it all.Overall, the Fibre Optic System offers some advantages such as:

- Low Total Cost of Ownership over time,

- Lifecycle Savings: reduce by 1/3 your costs with supply and installation,

- Early Warning & Improved Safety: identify hotspots early before they turn into a fire,

- Compliance: Certified Fire Detection solution (VdS EN 54-22, UL521, ULC S530, FM 3210, ATEX II(1) GD M2, KFI, CCC, SIL2),

- No Maintenance: reduce downtime, maintenance costs and eliminate device replacements,

- Well suited solution for hazardous environments such as mines, coal storage facilities, industrial plants and others.