An award-winning heat stress management program conducted by Leighton Contractors on the Australia Pacific LNG project resulted in zero heat stress related incidents despite the 45 degree heat, writes Karin Ng.

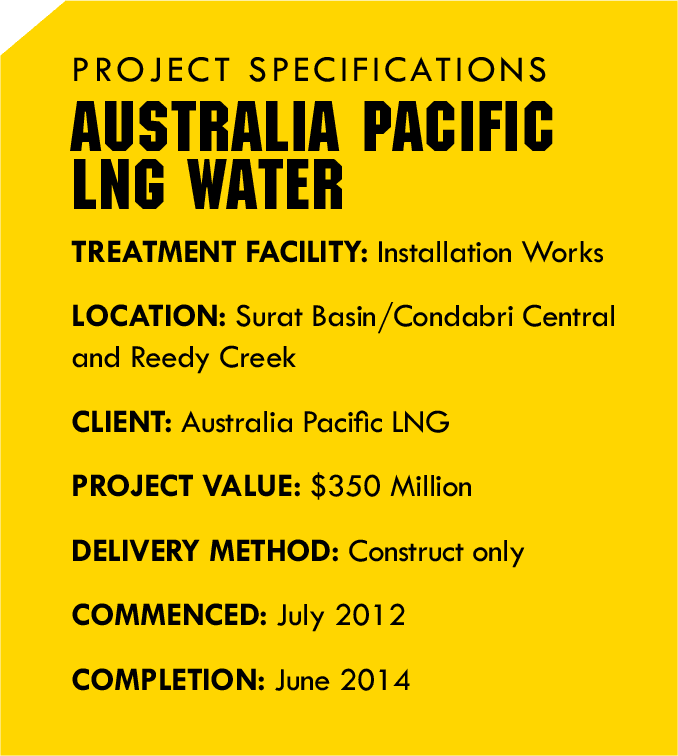

Due for completion in the second quarter of 2014, the Australia Pacific LNG Water Treatment Facility: Installation Works project is providing work for up to 800 people working on site on three shift patterns – making the safety, health and well-being of workers the project’s number one priority.

On behalf of Australia Pacific LNG, Leighton Contractors is constructing the water treatment facilities and storage ponds at Condabri and Reedy Creek sites. Once complete, the facilities will treat water produced by Australia Pacific LNG’s coal seam gas wells, with a goal of producing water that can be used for irrigation.

“The initiative has significantly reduced the risk of heat stress, despite air temperatures of 45 degrees and radiating temperatures of 57 degrees.”

Since mobilising to site in July 2012, the Water Treatment Facilitates team has proactively worked to prevent injuries, incidents and industrial related diseases on the project and experienced many successes in this pursuit. Most recently, the team received industry acknowledgement for its safety management, innovation and implementation of prevention strategies, such as its Heat Stress Management program, winning the Queensland Project Safety Excellence Award at the 2013 Queensland Major Contractors Association Awards.

Leighton Contractors’ Project Manager Simon Lewis said at project conception, heat stress was identified as a critical risk due to the project’s geographical location and timing of specific works exposing workers to high temperatures and risk of heat stress.

“To manage the safety, health and well-being of workers, the Heat Stress Management program targets zero heat stress related incidents – and I’m proud to say that to date the project has had no instances of heat stress related injuries,” Mr Lewis said.

“The initiative has significantly reduced the risk of heat stress, despite air temperatures of 45 degrees and radiating temperatures of 57 degrees.

Mr Lewis said ‘fitness for work’ had traditionally been accepted as purely drug and alcohol compliance. However, in consultation with Leighton Contractors’ internal subject matter experts, the project broadened its thinking to consider other factors in respect to fitness for work, of which heat stress is one.

“Since commencing the Heat Stress Management Program in November 2012, the project has not had a single case of a heat stress related illness.”

“When we were considering our safety approach to heat stress, there was little information of successful heat stress management programs and how they could mitigate the effects of heat related illnesses on workers, and its indirect impact on a project’s success.”

The project consulted health professionals such as 4CRisk and their Remote Area Paramedic Neil Hokins to assist in the development of the overall program.

Individuals working in hot conditions have a substantially elevated sweat rate, increasing the likelihood of dehydration by the end of their shift. By the time the thirst response is stimulated, humans are likely to have lost around two percent of their total body water, resulting in mild dehydration before project team members are aware of it. Strenuous labour or exercise in a hot environment may escalate sweat losses to several litres per hour. Dehydration also has physiological and psychological affect on performance.

Developing THE Heat Stress Management program

Heat stress was identified as a critical risk in the conceptual stage of the project due to the:

- geographical location of the project sites (Surat Basin in Queensland)

- strenuous physical occupations

- timing of specific works – daytime hours 6am to 6pm

- location of works (concrete structures, inside brine ponds, trenches, and potential for radiant heat, not normally considered as a ‘real’ risk).

The project’s objective was to have no heat stress related illnesses such as clinical dehydration, heat syncope (fainting), muscle fatigue (spasms, indirect musculoskeletal injuries due to fatigue) or more serious illness such as heat stroke.

A number of factors were considered in the project risk assessments to determine the scope of the heat stress management program. Environmental factors considered were:

- high temperatures

- wind speeds

- humidity

- night time storms causing higher humidity.

Activities at most risk were identified as:

- temporary works such as scaffolding and carpentry

- concreting

- steel fixing

- pipe laying

- High Density Polyethylene (HDPE) liner installations

- lagging of glass reinforced piping

- other areas of strenuous physical workloads (e.g. soil testers, earthworks labourers).

Other factors included:

- timing of works – 6am to 6pm on various rosters (e.g. 15 days working, six days off or 21 days working, seven days off)

- location of work – in brine ponds, trenches, highly reflective surfaces that radiate heat

- clothing – light weight and loose fitting

- physical exercise before, during and after work

- medication and its affect on workers

- physical condition of workers

- workers’ use of air-conditioning to cool down after work

- workers’ consumption of diuretics such as alcohol and coffee

- new workers from vastly different temperate and climates.

With the assistance of 4CRisk, the Heat Stress Management program clearly outlines the project’s processes and approach to mitigating the risk of heat stress.

The Heat Stress Management Program comprises:

- training programs providing:

- heat stress awareness on how to best manage heat before, during and after work

- technical training with selected safety professionals and supervisors on hydration testing – including the use and calibration of refractometers, providing mentorship to workers on hydration levels, how to undertake Thermal Work Load (TWL) monitoring, and how to effectively implement controls

- toolbox talks with supervisory staff, including subcontractors on TWL monitors in order to assess thermal work limits of workers

- Personal Protective Equipment (PPE) standards

- considered working hours and conditions

- self pacing

- guidelines for fluid consumption levels

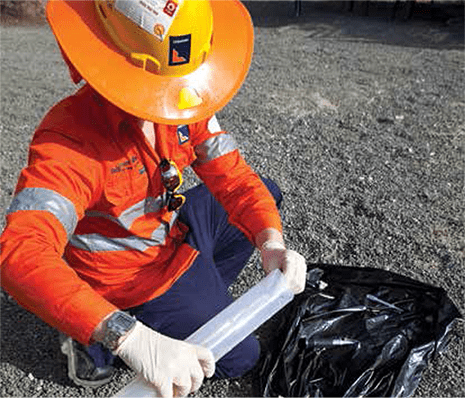

- hydration testing, including a urine testing protocol and rehydration guidelines

- meal break scheduling

- on-site health surveillance

- verification program – data logging and overseeing close-out of actions.

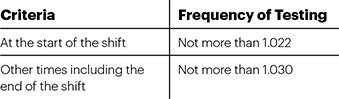

“By conducting hydration testing as part of fitness for work monitoring it has assisted us in determining a worker’s hydration status before work,” Mr Lewis said.

“More importantly, after the initial tests, we can undertake additional hydration tests including readings and measurement of specific gravity of urine, which determines increased concentration of solutes in the urine that can be associated with dehydration.

“Following these tests, we can provide instructions on a worker’s hydration status and provide rehydration guidance as required.”

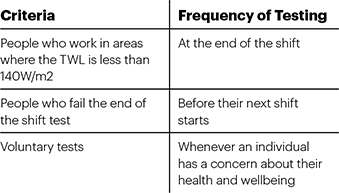

Ten per cent of personnel in roles requiring manual labour are tested daily using random and voluntary selection. Half of the random tests are undertaken at the start of the shift, and half at the end of shift. Additional hydration tests are conducted based on the below criteria according to the project’s testing protocol.

Note: Adults generally have a specific gravity in the range of 1.010 to 1.025. Increases in specific gravity (hypersthenuria, i.e. increased concentration of solutes in the urine) may be associated with dehydration.

When a worker fails a hydration test:

- the results must be communicated to the accountable supervisor

- the worker must not proceed to work, but drink small, regular amounts of cool water

- a re-test is performed after one hour and continues until the worker is adequately hydrated.

The project seeks further medical advice and where necessary, counselling, for workers who continuously fail hydration and fitness for work tests.

Planning Work

All supervisors are provided with instructions and training in the use of a Field Heat Stress Management Form. This provides a basic checklist to verify awareness, monitor resources and controls that are in place, and are considered, for the daily work scope.

When planning, scheduling and supervising work, supervisors have to consider:

- the workplace TWL

- arranging start and finish times to avoid the hottest part of the day

- programming heavy, physical work for the early or cooler times of the day

- conducting toolbox meetings, training programs, and meetings in cooler or air-conditioned areas

- recording data and taking the required actions to reduce the likelihood of heat stress illness.

During Work

Basic health surveillance is conducted during the initial phase of the implementation of the Heat Stress Management Program while manual labour is conducted in areas on the operation with a TWL of 140W/M2 or less. This is to ensure that there is no clinical evidence of significant heat strain (in the work group) for a particular set of environmental conditions.

Health surveillance includes the measure of heart rates, body temperature and weight loss. The purpose of this is to record the effectiveness of controls in work environments with a TWL less than 140W/M2.

| < 220 | Unrestricted Zone

|

| 140 – 220 | Acclimatisation Zone

|

| 115 – 140 | Buffer ZoneAny practicable intervention to increase the TWL above 140 must be implemented (i.e. providing shade or improving ventilation)

No more than 40 minutes per hour of sustained manual labour. All workers are permitted to self pace their work if longer breaks from sustained manual labour is required Hydration test at shift end |

| > 115 | Withdrawal Zone In addition to controls in the buffer zone the following must be applied:

|

The TWLM provides a thermal work limit which is the primary measure used to plan and manage work on the operation.

The TWL limits are designed to be applied to workers who are:

- well acclimatised

- self-paced

- well hydrated (TWL of 140W/M2 of less).

Limits and Controls

Risk treatment (control measures) as part of the Heat Stress Management Program includes a combination of engineering, administration and PPE control measures, coupled with behavioural controls determined by the thermal work limits from the TWLM.

These control measures are determined by the TWL and the corresponding ‘work zones’. Work zones include unrestricted work, acclimatisation, buffer and withdrawal zones.

Recording Data

The recording and updating of heat stress data from the TWLM is undertaken daily to provide evidence of recorded TWL and the controls implemented by supervisors.

Each supervisor or nominated professional is required to record on an hourly basis the TWL and the required controls dependent on the work zone readings.

Through daily monitoring of weather conditions, the project is able to prepare for heat events, relative to work scopes.

“By the time the thirst response is stimulated, humans are likely to have lost around two percent of their total body water, resulting in mild dehydration…”

Further Evaluation of Heat Stress and Electrolytes

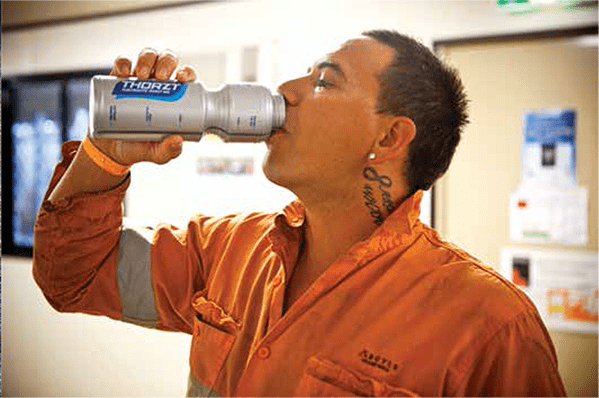

As a result of the intensive program, the project was approached by an electrolyte supplier (Thorzt) to undertake a thesis by University of Western Australia. This was a first on an Australian construction project. The study is examining the array of tests to determine how the voluntary versus regimented intake of water, or Thorzt, affect the development of thermal and osmotic strain in a hot workplace, and how that strain impacts on physical and cognitive performance.

Positive Outcomes

Since commencing the Heat Stress Management Program in November 2012, the project has not had a single case of a heat stress related illness. During the heat wave event in January 2013, where temperatures were above 50 degrees, the project achieved zero first aid, medical treatment or lost time injury cases due to heat stress, which is a significant achievement.

As a result of the success of the program to date, the program has now been rolled out on other Leighton Contractors projects and has since been adopted by our client Australia Pacific LNG, setting it as a benchmark in their project contracts.

ABOUT: Australia Pacific LNG Water Treatment Facility: Installation Works project

Australia Pacific LNG engaged Leighton Contractors to construct the water treatment facility in Condabri and Reedy Creek sites, referred to as the Water Treatment Facility: Installation Works. The project is constructing the water treatment facilities and storage ponds at Condabri Central (20km south of Miles) and Reedy Creek (130km west of Miles). The facilities will treat water produced by Australia Pacific LNG’s coal seam gas wells, with a goal of producing water that can be used for irrigation.

Australia Pacific LNG awarded Leighton Contractors with a further contract extension to upgrade Miles Aerodrome. The aerodrome project consisted of a runway upgrade to facilitate the landing of larger aircrafts. The extension is now complete and services the regional area.

Project scope of works include:

- bulk earthworks

- installation of sub-grades and underground services

- construction of permanent roadways

- grading and drainage

- construction of sediment ponds

- construction and lining of water storage and feed ponds and associated concrete structures

- construction of water treatment plants

- extension and widening of the existing runway – Miles Aerodrome.

ABOUT: Australia Pacific LNG

Australia Pacific LNG is Australia’s leading Coal Seam Gas (CSG) producer and is a joint venture between Origin, ConocoPhillips and Sinopec. Australia Pacific LNG is developing a multi-billion dollar, world-class CSG to LNG (Liquefied Natural Gas) export project.

ABOUT: Leighton Contractors

Leighton Contractors, a wholly-owned subsidiary of Leighton Holdings Limited, is one of Australia’s leading contracting and project development groups, with over $13 billion work in hand and employing more than 14,000 people across Australia, New Zealand, Papua New Guinea and Africa. The company delivers projects for clients across the infrastructure, mining, telecommunications, civil construction, industrial, energy, health and services sectors.

Add Comment