Lockout Tagout is an important safety practice that helps to provide protection to employees and contractors when they are working on plant and machinery.

Before commencing any maintenance on equipment it is important to isolate the equipment correctly to avoid any accidental start-up of machinery, which could lead to injury or worse. This is why Lockout and Tagout equipment is so crucial – it protects both employees and visitors.

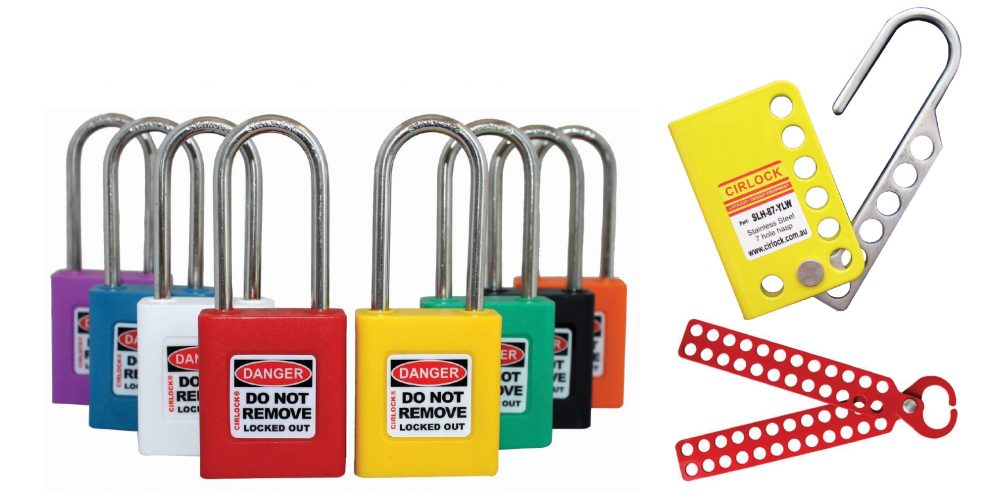

Lockout Hasps are one of the items extensively used in Lockout Tagout procedures. They are designed to provide maximum protection to workers whilst carrying out maintenance of plant and machinery. The locking facility on lockout hasps is ideal in group isolation situations – where more than one person is working on a piece of equipment at any one time. The hasp allows multiple Personal Lockout Padlocks to be applied to one isolation point together with a Lockout Device. This could be when multiple jobs are required to be carried out at the same time, or due to shift changes, where maintenance is taken over by another crew. The hasp is attached to the isolation point on the machinery. The person doing the work then attaches their personal padlock to the hasp. Any other workers who may need to simultaneously do maintenance on the machinery also attach their personal lockout padlocks to the hasp, preventing the machinery from being operated until all locks have been removed.

Every workplace should have Lockout tagout procedures in place. Below we have outlined a sample procedure with steps for consideration.

Step 1 – Detailed equipment information: Ensure all equipment is identified correctly and accurately, including its specific location.

Step 2 – Notify affected employees: When maintenance is going to be performed, all employees that may be affected should be notified. Let them know the timing of the work, and how long the equipment may be unavailable.

Step 3 – Shut down equipment properly: Detail, detail, detail! It is not enough to say, “disconnect the machine.” To ensure everyone’s safety and reduce the potential for damage, you must explain exactly, step by step how the machine is disconnected.

Step 4 – Disconnect all primary energy sources: Whether the primary energy sources include electricity, steam, water, gas, compressed air, or others, don’t assume that the person performing maintenance will know the correct procedure to follow. Again, explain exactly what needs to be done.

Step 5 – Address all secondary sources: While disconnecting the primary energy sources may remove much of the potential danger, it’s possible that there sources of residual energy, such as trapped heat in a thermal system, fumes that may need to be vented, or even tension in a spring assembly. Identify the process that will relieve any remaining pressure or other energy. Also consider other hazards, such as moving equipment that must be secured before work begins.

Step 6 – Verify the ISOLATION/lockout: Once you have disconnected all primary and secondary sources of energy, a test for dead must be performed to verify the isolation procedure has been successful.

Step 7 – RE-ENERGISING EQUIPMENT: When the work is done and all tools and other materials have been removed, the machine can be brought back into operation. The procedure should spell out the exact steps that are involved, along with the correct sequence.

Don’t forget… Keep procedures up to date

Equipment and operating procedures may change over time, and your lockout/tagout program needs to reflect those changes. Sometimes, the changes may be so minor that only the people working directly with the equipment are aware of them. That is why it is a good idea to review all your lockout/tagout procedures regularly to verify that they are still accurate.

To support your procedures, Cirlock have a full range of Lockout hasps, available in many different sizes, from 6 hole to 24 holes. Hasps are also available in Aluminium and Non-Conductive materials, as well as High Visibility Hasps.

Cirlock’s Lockout Tagout Padlocks come in 8 different colours, enabling individual locks to be easily recognisable for workers. While Red is primarily used for Personal Lockout, other colours can be used to indicate supervisors or different departments.

There are also various shackle sizes and shackle types (Non-Conductive and Stainless Steel) available from Cirlock, as well as options for your padlocks to be keyed individually or keyed alike to suit your requirements.

Cirlock padlocks can also be personalised with photos, names and phone numbers or branded with your company logo.

The full range of Cirlock products are available from your local Electrical Wholesaler, visit www.cirlock.com.au, email sales@cirlock.com.au and phone 07 5445 2910 for more information.

Add Comment