A new generation of real time dust monitoring has been designed to significantly improve the accuracy of data being collected, and mine worker safety in hazardous environments.

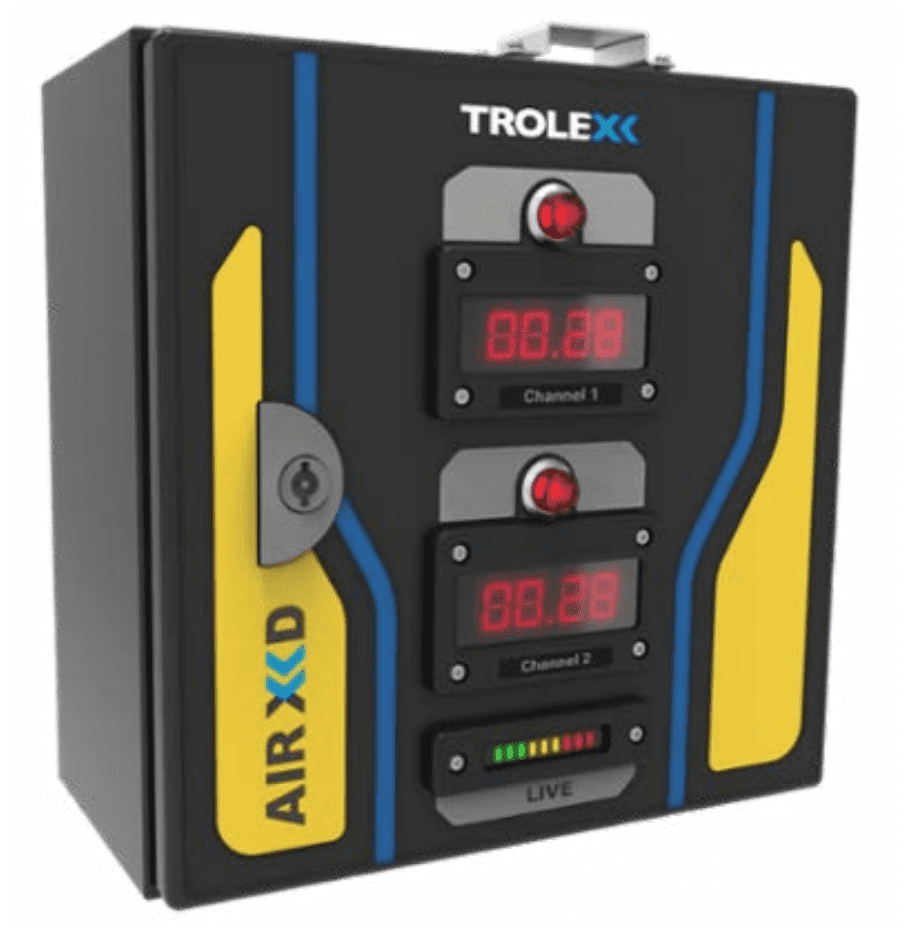

Trolex stated that unlike existing dust monitoring on the market, which can only be set to measure one particulate size at a time, the Air XD uses highly advanced particulate sensor laser technology to monitor multiple sizes of dust or silica particles at once – in real time.

The company added that this is the first time that multiple real-time dust monitoring has been deployed in hazardous environments.

Glyn Jones, the Group CEO of Trolex, said: “The monitoring of hazardous particles in the workplace is mostly self-regulated with reports being submitted to the [UK] Health and Safety Executive on an intermittent basis.

The real risk lies in the fact that those responsible for monitoring hazardous environments don’t have access to real-time accurate information. This vulnerability in the data potentially leaves workers exposed to hazardous particles that can cause illness later in life. In some cases, even death.”

The Trolex Air XD can provide mining companies with a level of hazardous particle detail that the company claimed has never been seen before in the industry.

As well as increasing safety, the Air XD can help improve productivity and provide cost savings within operations because they require less routine maintenance – removing the need for occupational hygienists and engineers to be sent onsite and lowering the overall cost of ownership.

The real-time application also allows operations to use live data to identify specific trends and peak levels of risk. This actionable insight can help improve safety procedures and protocols by reducing false alarms.

Jones continued: “The Air X series will provide mining organisations with a far better understanding of what is going on in their work environments. For the first time, they can use live, accurate data to ensure safety standards remain at the highest levels at all times.”

Real time dust monitoring achieves high accuracy levels

Trolex Air XD products use open-path laser technology in a completely new way, to measure the particle size in real-time. Using widely available connectivity technology, this real-time data monitoring can be connected both to workplace monitors/screens to inform workers on site and fed into a dedicated software solution at HQ to provide a complete picture of the levels of particulate across an entire operation.

The system also measures all particulates to provide a complete view of all particles of all sizes in the atmosphere, from ‘particle matter’ (PM) sizes ranging from 0.38um (very fine airborne particles/pollutants) through to 17.5um, and it detects all dust sizes simultaneously.

By differentiating between the different sizes of particles present, the Air XD products can provide a complete, accurate and reliable overview of the dust scenario at any time.

Furthermore, by using optical laser technology, and removing the reliance on any pump or filter, the Trolex Air XD can offer the same level of accuracy as achieved with the lab-based analysis – and enjoy a far lower maintenance overhead.

There is no need for calibration or component change, providing companies with a chance to immediately reduce the maintenance expenditure.

Read more Mining Safety News

Add Comment