There’s alot of speculation across the mining and rail industries regarding the cause of the BHP runaway train. Many people are asking how can an incident of this ilk occur in 2018 when we have safety at the forefront of what we do?

Across organisations like BHP, there are many safety related systems that have been implemented to prevent incidents…and yet a major one like this happens out of the blue. It’s not the first major incident by a mining giant recently, Peabody Energy lost control of a heating in the North Goonyella mine in September and, to date, have not re-entered the mine.

Fortunately, like the Peabody North Goonyella incident, there has been no loss of life. BHP and Peabody have only had to weather some substantial costs and reputational damage to their respective brands.

London BHP AGM hears “safety a priority”

Just last month we told at the BHP London AGM the importance of safety by the both Chairman and CEO of the global mining giant. Yet shortly thereafter, we are confronted with this significant safety related incident that makes us question if there is a disconnect between the boardroom and the pit bottom. Is work safety becoming an illusory goal?

While the ATSB are currently in an evidence gathering phase of their investigation, there will no doubt be many causative factors associated with this incident.

In the midst of the ATSB investigation, AFR has reported that BHP CEO Andrew Mackenzie has told shareholders that BHP had about 130 people working day and night to investigate the issue and repair the track, and he vowed to invest in improving safety.

“We lost control of the train through an issue with the systems,” Mr Mackenzie said.

“We’ve been all over this,” he said. “We will continue to invest to make our railways, as with all our operations, safer.”But he reiterated it was a deliberate derailment, instigated by BHP after it had lost control of the train.

“We lost control of the train through an issue with the systems,” Mr Mackenzie said.

Cascading system failures

The incident has clearly reflected cascading system failures which have impacted multiple train safety management systems, not just at one level in the organisation, or outside the organisation (i.e. regulators). Fortunately the final emergency system control worked effectively…the train was derailed.

Appreciating that its’ not just a failure of the driver is important in this case. Across Australia’s mining industry many people understand and appreciate that, in any incident, multiple system failures typically occur.

The key issues at this point are: why did these system failures occur? and what can be done to engineer out future system failures?

Safety systems research tells us that systems that typically make day-to-day tasks cumbersome will create inefficiencies in operations. Under these circumstances, users may find ways to shortcut the systems, thereby undermining the purpose of a continual use system. (McComb & Deshmukh, 2006) The small shortcuts then lead to cascading system failures which may result in incidents like the BHP runaway train.

Consultant says ‘uncertain’

Speaking to the ABC, Phillip Barker from Rail Safety Consulting Australia said the cause of the runaway train was unclear. He suggested the configuration or isolation of the brake system may have been a factor.

“Usually, once the driver leaves the train, the brakes are on, there’s procedures for that,” Barker said.

He added the driver would have sought permission to disembark the train to inspect the wagon, and procedures would have been in place to make sure the train didn’t move off without a driver.

The data recorder, or ‘black box’, might shed more light on the braking system’s operation, including applied traction power and brake pressure on the front and back of the train, according to Barker. Rail safety officers will interview the driver and rail controllers to find out what happened.

“They’ll be looking also at the safety systems … to see if they’re in place, if they’re adequate and if they were followed,” Barker said.

Is bureaucracy hampering safety?

We understand that progressively, many organisational safety systems have become bureaucratic in nature and are failing their intended purposes. They may fail to add value to the safety process and result in unintended consequences.

Greg Smith, a Perth based Lawyer and former safety practitioner in his book “Paper Safe“ suggests that bureaucracy hides the true state of safety and creates an illusion that safety is well managed, when it’s not.

We must wonder, did BHP have a safety system or rule in place that prevented the train driver to climb back onto a locomotive when it is moving, regardless of the speed, and did this contribute to the runaway? “Possible”…say some rail industry insiders have told AMSJ. “Risk of losing a driver or risk losing a train in this case is the matter at heart” they said.

Pressure is on the ATSB

Post the disaster, the ATSB now have some pressure. McKenzie already knows the issue…the ATSB just have to prove it from a regulatory perspective and we suspect it won’t be too difficult in view of McKenzie’s openness of the issues at hand.

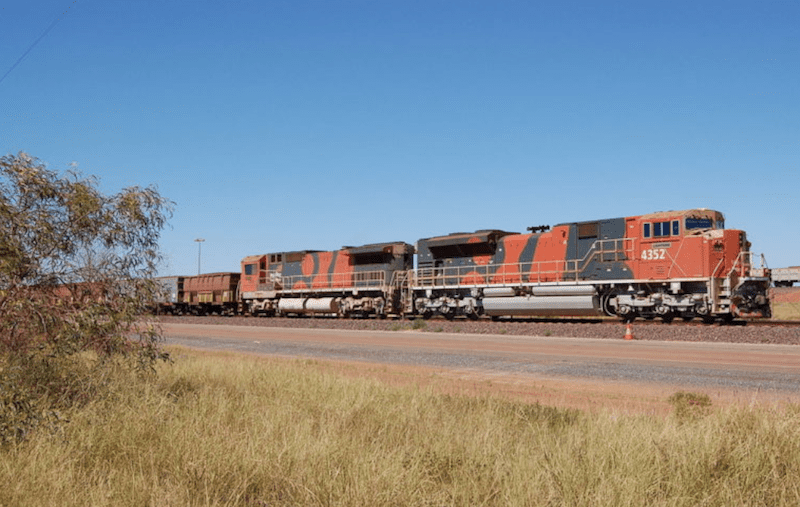

When a train, consisting of four locomotives and 268 wagons, travels without a driver for 92 km before being deliberately derailed at a set of points operated by a control centre…systems clearly failed.

Let’s hope there’s some learnings that the mining and rail industries can reflect on sooner rather than later and that the real cause of the BHP runaway train become clear before it can happen again.

Read more Mining Safety News

Add Comment