Resources Safety has issued an incident report regarding an accident on a WA mine site that resulted in a worker sustaining a compound leg fracture while unloading rolls of poly pipe.

Two freight truck drivers were delivering rolls of 100 mm diameter poly pipe to a mine when the accident occurred.* Each roll

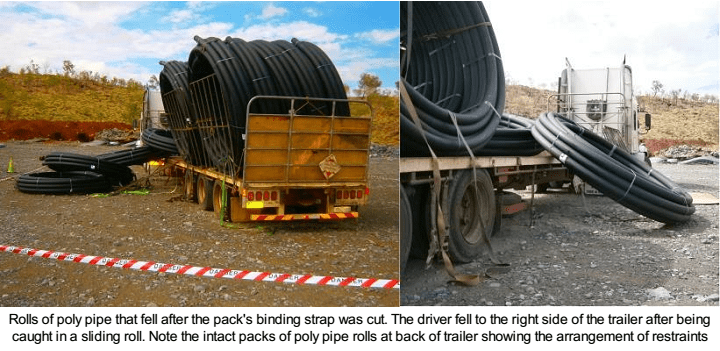

weighed more than 300 kg and were strapped together in packs of five standing upright on the trailer deck.

After releasing the restraints holding the packs on the trailer, the two drivers and site store person decided to release the straps binding the packs so the rolls could be unloaded individually.

One driver entered a pack of five rolls to release the two binding straps but was unable to release the ratchet on one strap. The second driver, who was standing on the ground beside the trailer, used a knife to cut that strap while the first driver was still inside the pack.

The pack separated and the rolls fell. Two rolls fell off the trailer. The middle roll landed half on the trailer. The remaining two rolls landed partly on the middle roll and partly on the trailer deck. The uppermost roll slid off the trailer on the other side, dragging the driver with it.

The driver fell to the ground, landing on his head and shoulder and sustained a compound leg fracture.

*In their Incident Reports, Resources Safety does not release the date of an incident, names of the people, or names of mines involved.

According to the Incident Report the direct causes of the accident were:

- There was uncontrolled movement of the rolls of poly pipe when the pack’s strap was cut.

- The truck driver was positioned inside the pack when the poly pipe rolls moved.

- The truck driver was working at height without fall protection.

Contributory causes

- Although a site procedure was available for loading and unloading, the hazard of stored energy and the need to undertake a job-specific risk assessment were not recognised.

- The store person and truck drivers had not unloaded packs of poly pipe rolls of this size at the

site before. - The method and equipment required to safely unload the pipe packs from the trailer had not

been communicated to the truck drivers or store person. - The binding strap ratchet could only be operated by a person standing inside the pack.

- The style of binding strap ratchet was unfamiliar to the truck drivers.

Recommended actions include:

- ensuring personnel loading and unloading freight understand the hazard of stored energy and

have the information, equipment and training necessary to handle freight safely - reviewing site freight unloading procedures and adequacy of risk management controls,

including the need for specific risk assessments where job parameters have changed.

Dumb ass is all I can say

Reading this report really makes me wonder about the calibre of people being employed in mining. The whole thing reads like a Marx brothers routine