RINGSPANN, is a leading German manufacturer of specialised power transmission products, was founded in 1944 with headquarters in Bad Homburg near Frankfurt, Germany. The group is a leading technology manufacturer in freewheels, brakes, shaft-hub-connections (i.e., Locking Assemblies, Shrink Discs, Rigid Shaft Couplings, Locking Elements), overload clutches and couplings, precision clamping fixtures and remote control systems.

With nine manufacturing facilities in Germany and other countries, RINGSPANN’s service portfolio ranges from consultation, design and development, production of ready-to-install components and include customer training and after sales support. RINGSPANN is considered a premium manufacturer in all of the above product segments and is an international market leader in the area of freewheels. In Australia, we have a dedicated office in Melbourne since 2018 to service our customers with great support and technical know how.

Here are some of RINGSPANN’s key product offerings for the power transmission industry.

RINGSPANN FREEWHEELS

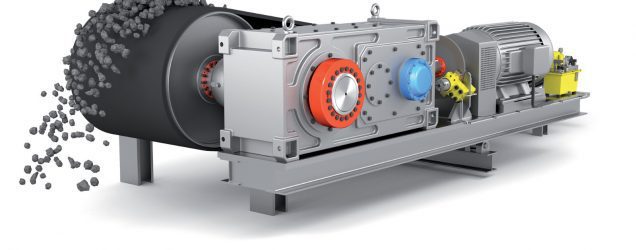

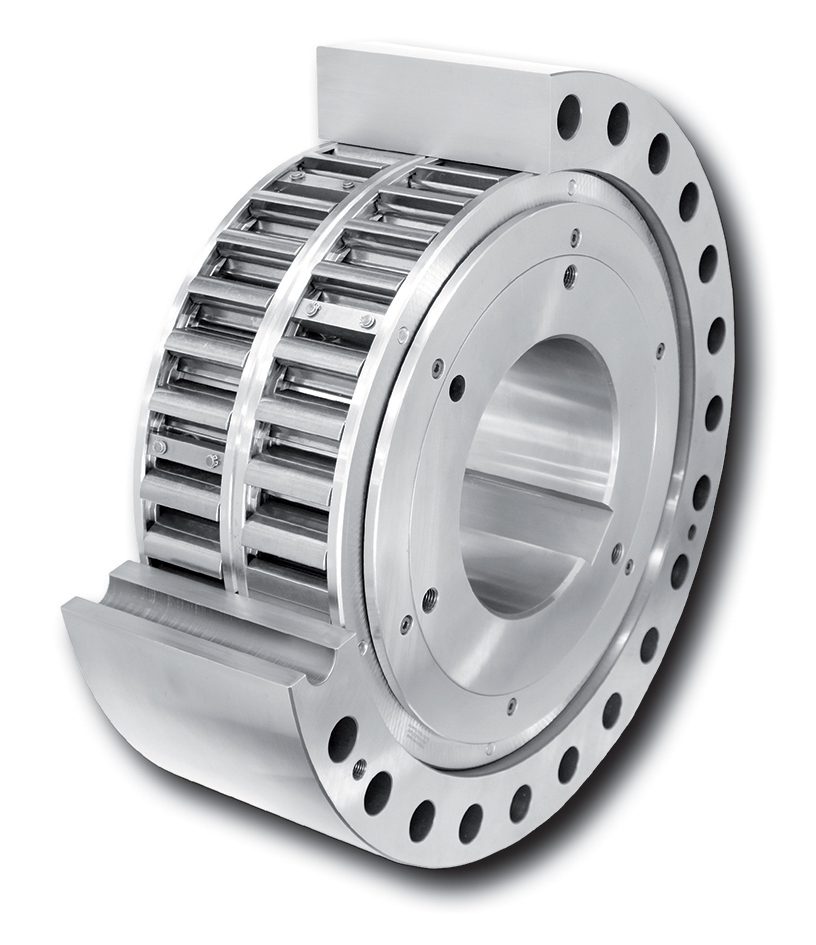

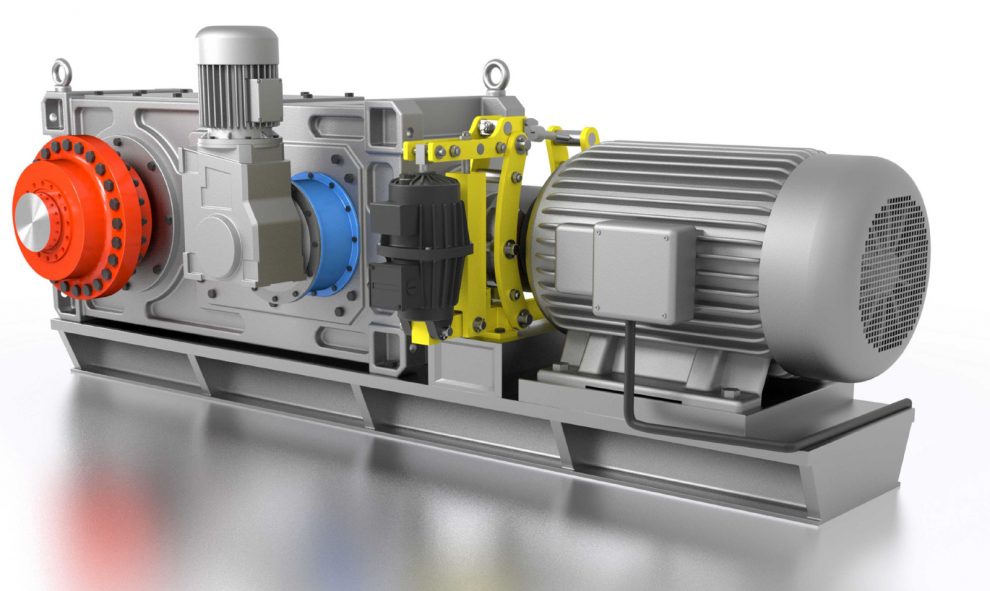

RINGSPANN freewheels of the FXM series launched in 1971 have been setting the global standard for almost 50 years. These are a standard feature of drive trains on numerous international machines and plant construction. Equipped with the legendary “Sprag Lift-Off Type X” offer low lift-off speeds and wear-free continuous operation. Precision and compact design of the internal elements is a pioneering development of RINGSPANN design & engineering department. They offer a low maintenance ‘fit and forget solution’ on industrial drive trains.

The entire FXM series, comprising of more than 40 standard sizes, have race diameters from 31 to 750 mm and they generate torques ranging from 110 Nm to 1,230,000 Nm and are typically used as backstops on intermediate shafts of spur gearboxes in conveyor pulley drives or as overrunning clutches.

The FXM series has been continuously developed over the years and adapted to new areas of application time and again. It is one of the reasons why RINGSPANN engineering has a remarkably high level of design competence for this incredibly versatile freewheel type.

Technical data sheets, 3D CAD models and installation instructions can be found on www.ringspann.com.au.

RINGSPANN BRAKES

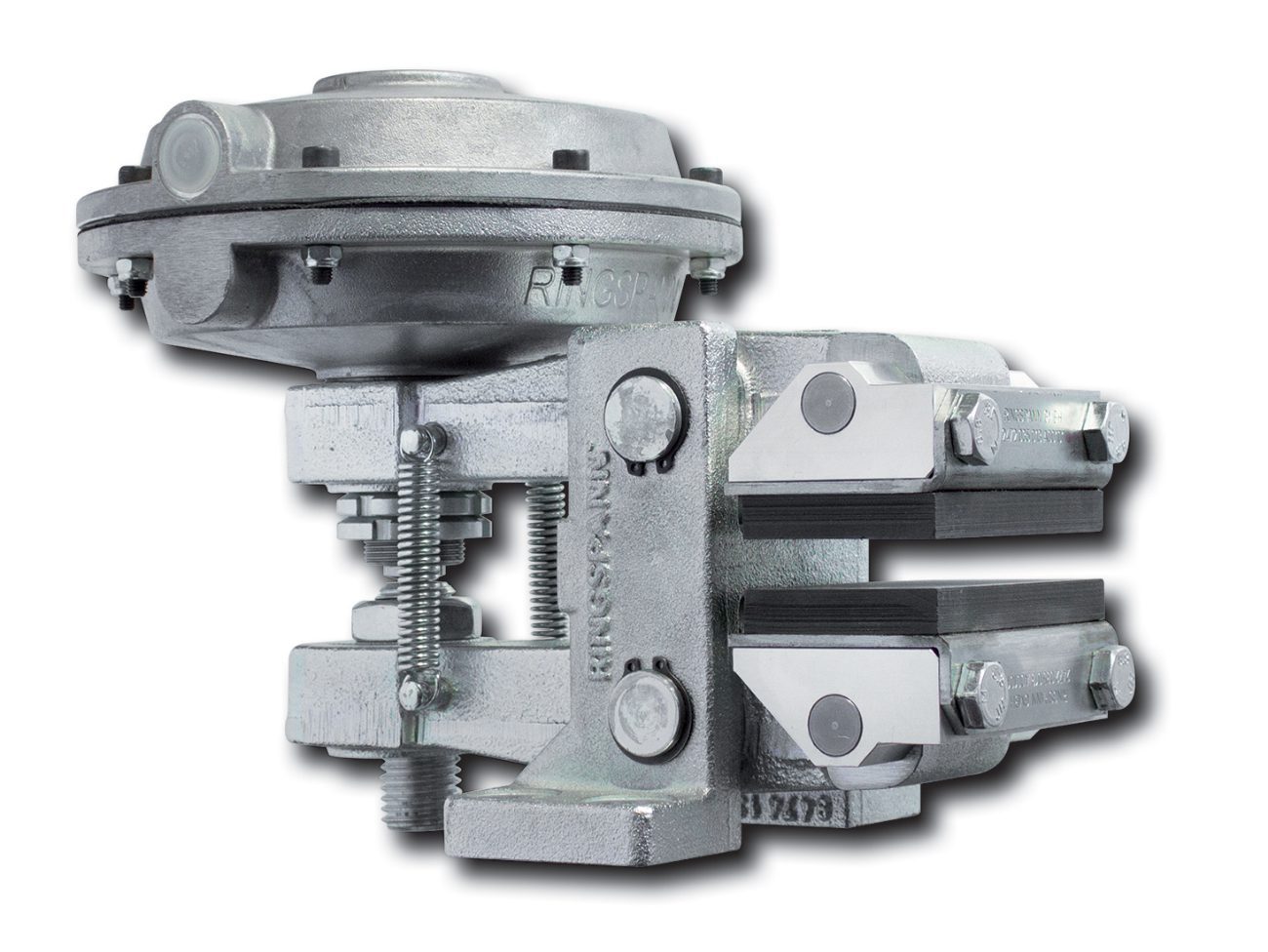

RINGSPANN pneumatic, hydraulic and electromagnetic brake calipers handle braking torques of up to 40,000Nm for general mechanical engineering applications. Our hydraulic brake calipers achieve higher braking torques of up to 600,000Nm for wind turbines and demanding mining applications. Some of the installations in drive technology and machine construction requiring smaller braking torques up to a maximum 8,000Nm are covered by our compact and lightweight electromagnetic disc brakes.

The brake calipers from RINGSPANN’S new series DT / FEA / H-ST are much slimmer in design than conventional industrial drum brakes due to a space saving constructional variation.

RINGSPANN’s electromagnetic disc brakes from its DH and DV series as well as EV and EH series are a preferred choice for various braking applications like stopping, control and holding with braking torques ranging from 94 to 6,590 Nm.

RINGSPANN have developed an online brake calculation tool on our website www.ringspann.com.au for selection based on important parameters like mounting, brake disc form, friction block wear and ambient temperature and to determine braking torque and clamping force on a specific brake disc diameter.

RINGSPANN LOCKING ASSEMBLIES & SHAFT-HUB CONNECTIONS / SHRINK DISCS

RINGSPANN’s locking assemblies are based on a superior frictional connection, the technical underlying principle and we intend to remain faithful to this fundamental principle. All our attention is devoted to the ongoing further development of the frictional locking principle and we are focused on the targeted influence of the key factor, the coefficient of friction. We have our own testing facility for research and quality assurance.

Synergies from our other product groups such as freewheels, clutches, brakes, couplings, force and torque limiters help with development work in the field of locking assemblies. Purchasers of our products will find key technical and design features on our website that will assist with selection.

The product range currently offers 25 shaft-hub-connection series for torques from 0.16 Nm to 4,225,000 Nm, comprising of shrink discs, locking assemblies, locking elements (also called cone clamping elements), rigid shaft couplings, star discs and star spring washers and clamping systems for mounting torque motors.

In the area of shaft-hub-connections connected via friction lining, shrink discs rank among the most important drive elements and RINGSPANN’S three-part shrink discs were introduced to the successful standard series RLK 603 S, for conveyor systems, stirrers, mixing plants, construction machinery and wind turbines. These offer powerful externally clamping connections with their very high torque capacity across a range from 18 Nm to 156,700 Nm.

For all your power transmission equipment requirements, please contact RINGSPANN Australia’s technical team on info@ringspann.com.au or 03 9069 0566 and visit www.ringspann.com.au.

Add Comment