Factors that make for safe work practices on mining sites are multi-faceted. Some are highly visible and costly. Others protect workers in ways that are mostly unheralded and with a minimum of fuss and cost.

Extension leads supplied by Powersafe Products significantly reduce risk of electrical onsite incidents thanks to a feature that is virtually undetectable.

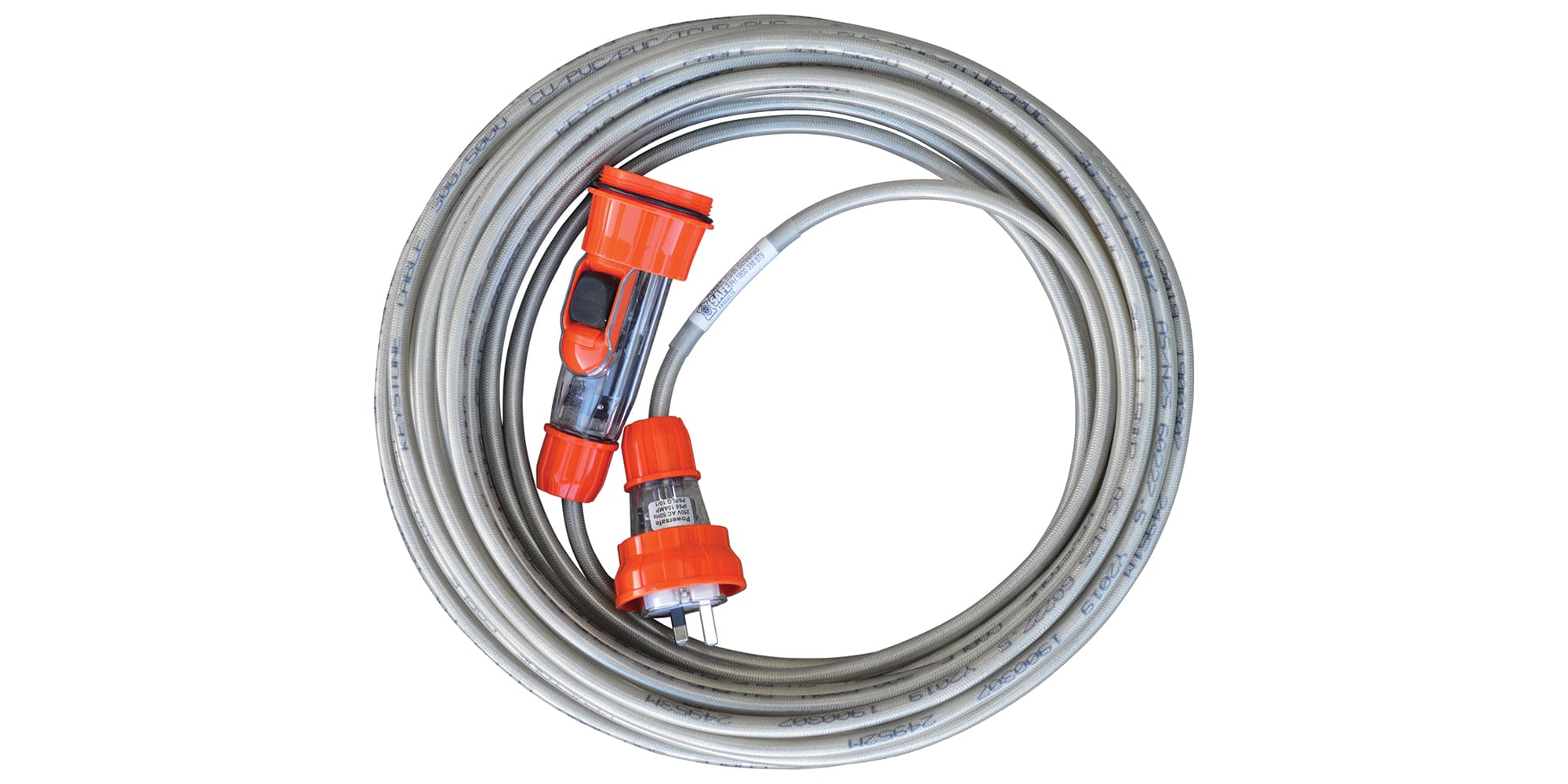

While appearing like any other 240v or 3-phase extension lead, a tinned copper-braid which provides an extra layer around the inner assembly can potentially save personnel from electrical injury.

In the event of a sharp or heavy object falling on a standard lead without the copper-braid layer, there is a possibility that dangerous electrical currents can pass from the severed lead into attached or nearby machinery. The danger in wet conditions becomes even greater.

However, with Powersafe’s extension leads, with the tinned copper braid connected to the earth pin at the plug and socket end, upon severing or damage to the lead, the RCD or earth safety device will be tripped, and the flow of power instantly stopped, preventing risk of injury to personnel or damage to equipment.

In addition, the three-phase leads are covered by UV stabilised neoprene sheathing, which is resistant to oils, chemical corrosion and weathering, able to be used in wet or dry conditions, and is available in 20A, 32A, 50A, 63A, in various lengths and in either safety yellow or black.

PRODUCT SPOTLIGHT

Braided Extension Lead

Powersafe’s braided extension leads provide an extra layer of safety thanks to the addition of a copper braid around the diameter of the cable, which is then covered by the UV stabilised outer sheath.

- Conductor – Fine Wire Tinned Annealed Copper

- Filer – Non Hygroscopic PP Filler

- Insulation – Cross Linked, Polyethylene

- Screen – Aluminium Laminate Tape

- Braid – Tinned Copper Wire Braid

- Separator – Polypropylene Tape

- Jacket – UV Stabilised Sheath

On any site where there is high levels of traffic and activity, Powersafe’s earth-screened extension leads will give management and workers peace of mind.

Switched extension lead socket

Another innovation in extension leads from the PowerSafe team is the switched lead socket, which can both potentially save significant amounts of work time over the course of a year and increase the safety of on-site workers.

Consider how much time is spent, walking to and from equipment and power source to prepare for maintenance or repair, for example, changing a grinding disk or drill bit.

“On any site where there is high levels of traffic and activity, Powersafe’s earth-screened extension leads will give management and workers peace of mind.”

Sites’ risk assessment audits found that on many occasions, workers would leave equipment on during maintenance simply to save time and/or effort – a small oversight that leads to multiple risks to life and machinery.

With an IP66 switched 10A or 15A lead socket, safe and reliable switch-off is available right there at the tool rather than at the power source. An LED indicator light offers additional safety.

Developed in-house and fully certified for use in Australia, the switched lead socket is one of those innovations that causes us to wonder why it wasn’t developed years ago – simple yet profound – and bringing a new level of electrical protection to worksites Australia-wide.

The Powersafe advantage

Mining sites around the country and overseas use Powersafe’s extension leads, together with their huge range of high quality, multiple outlet portable power distribution boards and accessories.

A large part of Powersafe’s business comes from their ability to build custom boards to meet the specific requirements of individual sites. Building these boards in their factory on the Sunshine Coast allows Powersafe to meet client specifications and supply in a timeframe the competition can only dream about.

Also stocking cable covers and lead stands, Powersafe is the one-stop shop for your power distribution requirements.

As an ISO certified organisation, customers are assured that Powersafe Products is a credible and trustworthy manufacturer, distributing products of the highest quality, with an emphasis on safety and innovation.

Safety and usability are the focus, with Powersafe Products maintaining the highest level of safety in all products manufactured

All Power Distribution Boards are fully IP66 tested not just the outlets, after all what’s the point of having an IP66 outlet if it is mounted to a bucket.

Unlike many of their competitors Powersafe test and have Individual Australian Compliance Certificates for all items usedin the manufacture of their equipment including outlets, boards, breakers, and cabling. Most of their boards are manufactured in their Australian facility by certified electricians, with the remaining products undergoing stringent testing (supplied with test results) prior to being sold.

Offering an unparalleled five-year pro rata warranty, Powersafe strives to manufacture and supply the highest quality products on the market. After recently returning their manufacturing processes to Australia, upgrades have been made to almost all of products.

Distribution in Australia is via electrical, tool and welding wholesalers, and via Powersafe distribution hubs in Queensland and Western Australia. International markets include South Pacific, PNG and UK.

To contact Powersafe directly to discover more about their products and services, go to their website at www.powersafe.net.au or ring 1800 338 979.

Add Comment