Source: Department of Mines and Petroleum, Resources Safety

22 December 2014

Summary of hazard

Over the past three years, the Department of Mines and Petroleum has received more than 160 electric shock incident reports during welding on Western Australian mining operations. Fortunately, no one has been electrocuted but any shock received during welding has the potential to be fatal.

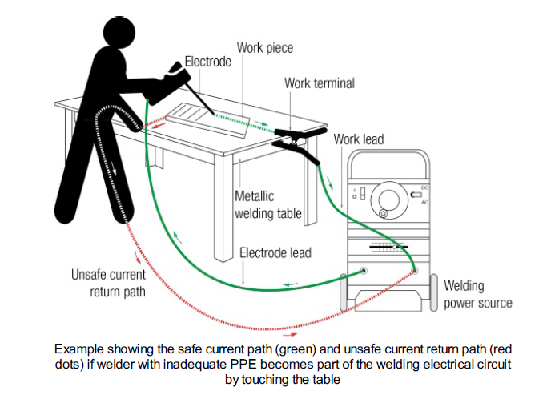

The welding electrical circuit comprises a power source, electrode lead, electrode, work piece, work terminal and work lead. An electric shock may result if a person becomes part of the welding electrical circuit during welding.

Contributory factors

The most common ways that a person becomes part of the welding electrical circuit are by:

- inadvertently touching exposed metallic or conductive parts during welding

- welding in wet or humid conditions, which increases the risk of inadvertent contact through water or sweat, which are conductive

- not using fit-for-purpose personal protective equipment (PPE)

- using a welding electrical circuit that is faulty due to inadequate testing and maintenance.

Actions required

Workers need to be competent in the tasks they undertake. Those involved in welding should understand the welding electrical circuit and how to maintain a safe current path.

Safe work procedure

A safe work procedure for welding work should be developed and implemented in accordance with Australian Standard AS 1674 Safety in welding and allied processes and the Welding Technology Institute of Australia’s Technical Notes 7 and 22. This includes:

- conducting a job-specific risk assessment

- implementing measures to mitigate risks arising from the work environment

- visually inspecting the work environment, welding equipment and welding electrical circuit before

- each welding job.

Work practices

Welders should:

- be aware of their work environment to avoid becoming part of the welding electrical circuit (e.g.know what should not be touched)

- ensure there is adequate insulation of welding electrical components to avoid inadvertent body contact with any exposed live electrical part

- connect the work terminal as close as practicable to the work piece to provide the least resistant current return-path back to the welding power source

- ensure earth leakage protection does not exceed 30 mA

- isolate the welding activity from other work carried out in the area Note: Where it is necessary to carry out more than one welding activity in the same work area,

a safe current return-path should be maintained for each welding activity. - avoid welding in wet or humid work areas

- use protective devices such as a voltage reduction device (VRD) or manual trigger switch.

If it is not practical to avoid working in wet or humid conditions, implement additional control measures such as:

- ensuring equipment is dry before welding

- using fit-for-purpose personal protective equipment (PPE) and clothing (e.g. personal protection that insulates body parts from any exposed metallic conductive parts of the welding electrical circuit)

- providing additional PPE for change-out when that being used becomes wet or damp.

Testing and maintenance

An electrical supervisor at a mine must ensure that electrical equipment and installations at the mine are maintained in a safe working condition through routine testing and maintenance by a licensed electrician. The test plan should include verification of:

- the welding electrical circuit

- protective devices

- earth continuity and insulation resistance.

Further information

AS 1674.2 Safety in welding and allied processes

The Welding Technology Institute of Australia (WTIA)

Technical Note No. 7 Health and safety in welding

Technical Note No. 22 Welding electrical safety

This Mines Safety Bulletin was approved for release by the State Mining Engineer on 22 December 2014.

For more information visit the DMP website: http://www.dmp.wa.gov.au/15563.aspx#7061

Add Comment