Authorities have released a reenactment of a resources employee being pinned under heavy equipment.

A recent video illustrates the terrifying moment a male worker became trapped under a loader cab weighing between 548- and 794- kilograms at Graymont’s Attunga mine, 22km northwest of Tamworth.

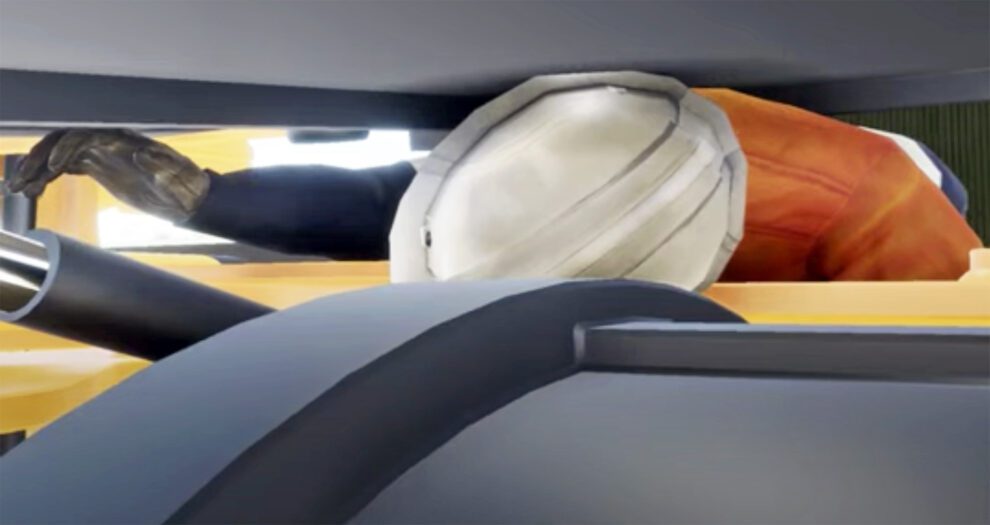

The shocking images commissioned by the New South Wales Resources Regulator show the CJD Equipment contractor approach a Volvo L220H wheel loader, tilt the cabin and climb underneath on 30 November 2020. The cab suddenly lowers onto his upper body, trapping the victim between the cab and chassis while completing maintenance work.

The maintenance field service technician ended up being pinned under the cab for up to five minutes since he worked alone.

“The worker was able to call out for help from mine workers who were having a meal break in a nearby room. The mine workers rescued the worker by raising the cab, … called emergency services and stayed with the worker until the ambulance arrived on site,” the October 2022 final investigation report said.

“The worker was transported via ambulance to Tamworth Hospital where he was assessed in the emergency department and released that evening. The worker received treatment for soft tissue injury but was not admitted as an in-patient at hospital.”

Investigators found the cab tilt function was unsafe due to the risk of self-lowering without warning or control. They claimed the worker should not have positioned his upper body, head and limbs in the 300–330 mm gap without a secondary support device. They also discovered this behaviour contradicts safety precautions listed in the Volvo PROSIS service manual.

The following recommendations were made:

- develop and implement safe systems of work (including procedures) directed toward assessing health and safety risks, including those arising when mobile plant is used in a way not intended by the designer

- take the ‘line of least resistance’ or self-impose time constraints when carrying out a task to reduce time and effort that could compromise safety

- apply the hierarchy of controls to eliminate or minimise health and safety risks like suspended loads, crush hazards and infrequent work tasks

- mechanisms that hold a suspended load at any position in the cycle of opening or closing should be designed for inherent safety between closed and open positions

- a suspended load must not be released from a seemingly stable position without operating controls

- add administrative controls, procedures and information or warnings to OEM manuals

- eliminate or minimise health and safety risks.

Click here to watch the video.

Click here to read the full report.

Related articles

Truck cabin falls onto mine worker

Middlemount mine worker crushed to death at Grasstree mine

Mining contractor fined $115,000 over death of worker

Operator loses consciousness when head becomes trapped.

Add Comment