In a bid to cultivate a sustainable graphene-centric industry both in Australia and globally, the University of Adelaide’s ARC Graphene Research Hub made achievements in the manufacturing and application of graphene.

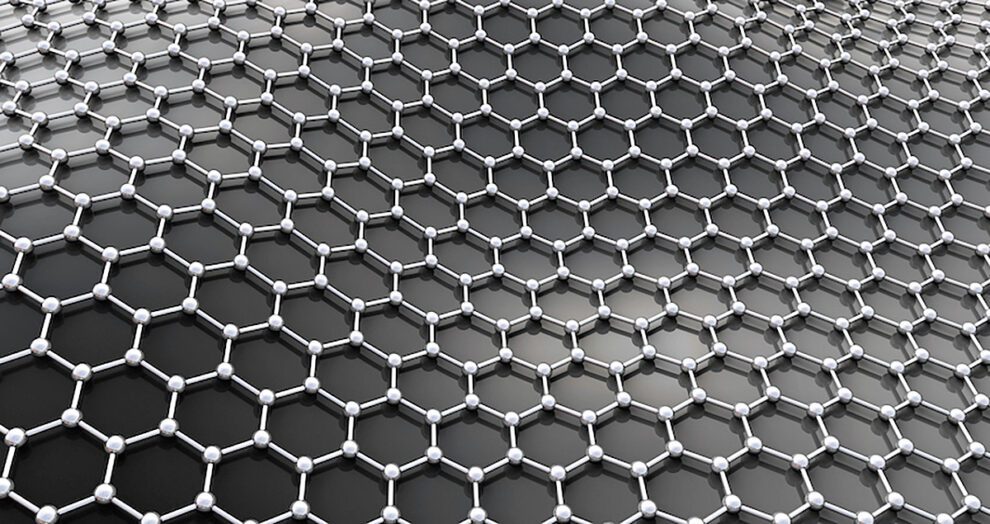

Graphene, a nanomaterial derived from carbon, boasts extraordinary attributes. Its unique single-atom carbon lattice configuration renders it a strength that is two hundred-fold greater than steel. Additionally, it exhibits exceptional conductivity for both heat and electricity. A striking feature of graphene is its sheer thinness combined with its lightweight nature – a mere gram of this material can span an entire football pitch.

Furthermore, graphene’s versatility lets it seamlessly integrate its properties with other materials and products it is amalgamated with.

Professor Dusan Losic, who leads the School of Chemical Engineering and Advanced Materials, has researched potential applications of graphene, particularly in enhancing properties of other materials.

Highlighting one such application, Losic said, “Cement, an indispensable construction material, unfortunately, results in significant carbon dioxide emissions during its production. Our team has discerned that infusing a minimal quantity of graphene into cement considerably diminishes the carbon dioxide emissions during its manufacture and application. This not only enhances the cement’s resilience and longevity but also presents an eco-friendly alternative.”

However, the industrial-scale production of graphene has historically been a challenging and costly endeavour. Addressing this challenge the Graphene Research Hub, in collaboration with their industry ally, First Graphene, has innovated an electrochemical technique. This method transforms graphite rocks into graphene, yielding premium-quality graphene powders. The process is promised to be cost-effective, energy-efficient and environmentally friendly, eschewing chemical waste and extensive labour.

First Graphene has adeptly upscaled this procedure at their production facility in Western Australia. They are on the cusp of becoming one of the globe’s predominant graphene producers, offering quality graphene at competitive prices for global enterprises.

What lies ahead

Equipped with these enhanced manufacturing techniques, researchers are crafting novel graphene-infused products and technologies. These innovations aim to address pressing challenges in sectors like energy, environment, climate change and agriculture. Current projects encompass biosensors employing highly conductive graphene inks for disease diagnosis, protective coatings, advanced energy storage devices and innovative graphene-based adsorbents adept at purging toxic contaminants from soil and water.

The dynamic ensemble at the ARC Graphene Research Hub is touted to further these groundbreaking ideas, propelling the growth of a sustainable graphene industry across the nation.

Related articles

33 per cent of procurement teams ‘cut corners’ says report

Workers exposed to silica are more likely to develop black lung says study

Mine accommodation exceeds safety limits during lockdown

Number of work fatalities drops across industry.

Add Comment