A US-based teenager has developed a unique blind spot reduction system that may have application in reducing pillar blind spots and improving operator field of view in mining vehicles.

14-year-old Alaina Gassler from Pennsylvania designed a prototype system for removing vehicle blind spots and fitted it to her families Jeep.

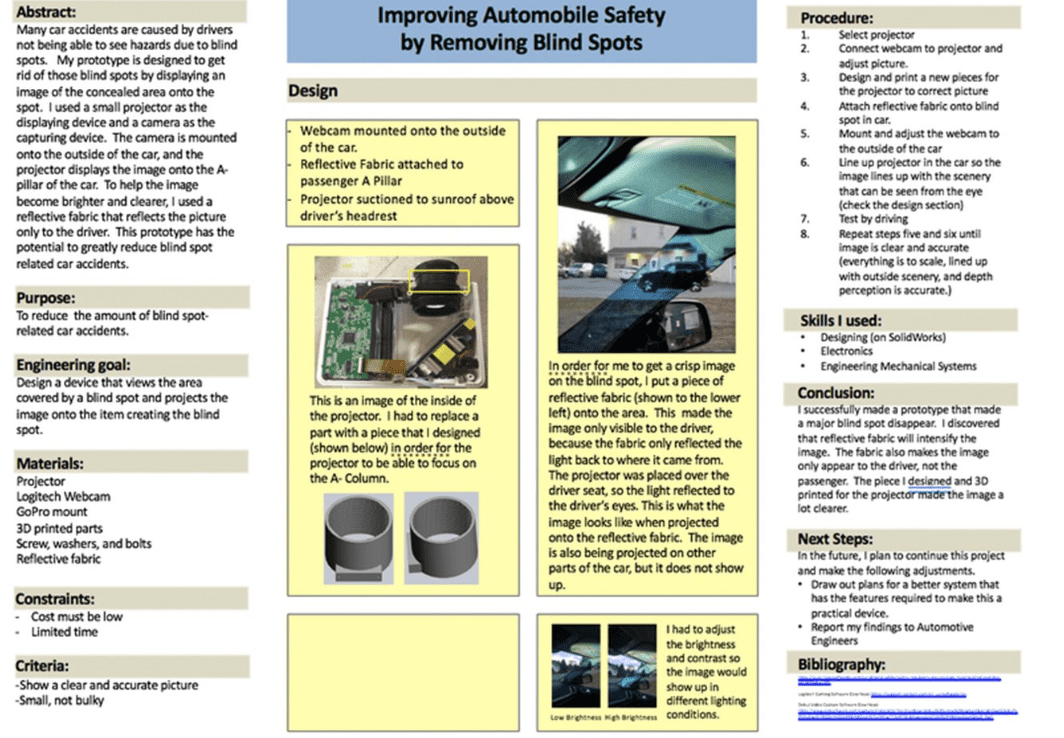

Gassler used a simple webcam placed on the outside of a vehicle A-pillar to capture a vision of the blind spot and then linked it to a small projector that projects the image on the inside pillar of the vehicle (See Video below)

The pillar is coated with a non-reflective fabric to ensure the image is clean.

Gassler explained to Popular Mechanics that the reason she decided to create the fix was that, in part, her grandmother scraped the side of her car due to the blind spot.

“I wanted to find a way to get rid of them,” Gassler said. “My older brother, Carter, just started to drive, so it was a big safety concern.”

The solution is believed to have application in the mining industry globally to improve operator field of view for surface vehicles. While mining trucks and loaders have engaged the use of the range of a range of technology to remove blind spots, the teenager’s innovation is a practical low-cost solution to improving the field of view through ROPS pillars.

The new system developed by the teenage could greatly enhance the operator field of view. Refer ISO 5006:2017 Earth-moving Machinery — Operator’s field of view — Test method and performance criteria.

Read more Mining Safety News

Add Comment