The drilling industry is a cornerstone of mining, involved in exploration and production activities as well as providing a range of associated services (e.g. water bores). Crews often work in challenging environments using sophisticated drill rigs and support vehicles.

This specialist working environment has the potential to expose workers to many hazards including working at heights, manual handling, and the uncontrolled release of stored energies associated with plant (e.g. hydraulics, compressed air systems) and equipment.

Safety in the drilling industry has progressed significantly compared to the practices of the 1980s and 1990s. Hard hats and other personal protective equipment (PPE) have replaced tans, shorts and shoes. Manually running rods using the hook and clam shell has, for the most part, been replaced by remotely operated rod handlers. Other improvements include the guarding of rotating drill string, whip checks on compressed air hoses, and the use of rated fittings and fit-for-purpose tooling rather than modified equipment.

As technology advances, so increasingly has the requirements and safety expectations of exploration and mining companies. Drilling companies must comply with mining company procedures to be awarded the contract. Many in the drilling industry have demonstrated their willingness to adapt and change to recognised methods of drilling safety.

As the mining industry evolves towards a resilient workplace culture, there is the need to be more proactive. The focus is on developing realistic and effective controls, moving away from a reliance on administrative and PPE controls.

Fourteen drilling workers in the Western Australian mining industry have died in work accidents between January 1, 1965, and June 30, 2015. On average, this means one drilling worker was fatally injured about every three-and-a-half years. Thankfully, there has not been a drilling employee death in Western Australia since 2007.

How can the regulator, drilling and mining industry work together so this fatality-free period continues as we strive towards the aspirational goal of zero harm? We need to build on what has already been done, understand the hazards, manage the risks, and use resources effectively to maximise control measures.

Understanding legislation

To move towards a safer working environment an understanding of the legal responsibilities that a company has under the Western Australian mines safety and inspection legislation is vital. Some duty holders appear confused about their key responsibilities and the legislation that applies. Some key areas are described below.

Note: This information is not exhaustive, contractors and mining operations should ensure they conduct a specific review of the legislation to ensure compliance.

Drilling accident and incident reporting

Currently, there is probably under-reporting of accidents and incidents in the exploration sector compared to mining and mineral processing. As contracting plays, a major role in exploration, an understanding of the duty of care of all parties and reporting lines is fundamental to providing and promoting a safe workplace.

Reporting accidents and incidents are one such facet and allow the regulator and industry to identify where there are uncontrolled hazards and share the lessons learnt. By understanding the mechanisms and identifying trends, even low consequence events (e.g. near miss) can assist in preventing high consequence events (e.g. serious injuries and fatalities).

READ RELATED CONTENT

Exploration activities are considered to be part of mining operations (section 4 of the Mines Safety and Inspection Act 1994, see glossary), and are subject to the mines safety and inspection legislation. Under the Act the regulator must be notified of:

- accidents involving disability [ s.76]

- some occurrences at mines [s. 78]

- some potentially serious occurrences [s. 79]

Contractors need to report accidents, occurrences, and potentially serious occurrences to the exploration manager or the onsite person responsible for exploration activities in a timely fashion. The manager or responsible person must then submit a report to the regulator through the online Safety Regulation System (SRS) and may also contact a mines inspector.

When industry investigates reportable accidents and incidents the root causes and hazards should be identified and risk addressed. Everyone benefits when these learnings are shared with workers and industry. The potential for recurrences, losses to both the workforce and production, and the consequences of potential future incidents can be reduced.

Drilling safety – training & equipment

There are requirements under the Mines Safety and Inspection Regulations 1995 for employers to ensure employees engaged in exploration operations are provided with training and equipment appropriate for hazards they will be exposed while working [rr. 3.6 and 3.7].

There are specific requirements for the training and competence of drilling crew employees [r. 3.9].

Plant

A contractor supplying plant, a principal employer, or a driller needs to read and understand Part 6 of the Mines Safety and Inspection Regulations 1995, which details plant safety. Key points are:

- Designers and manufacturers of plant have responsibilities [rr. 6.3 and 6.6]. Ensure they have met their obligations and supplied you with legally compliant plant and equipment.

- As an employer you must identify hazards associated with plant and conduct risk assessments, reduce the risks identified and prevent unsafe use of plant [rr. 6.17, 6.18, 6.21].

Earth disturbing operations – provision of information

Regulation 3.3 applies to any exploration operation that involving the disturbance of earth (including drilling, costeaning or trial pit excavation). The exploration manager is required to notify the senior inspector of mines for the region where exploration activities take place.

Safe systems of work in drilling

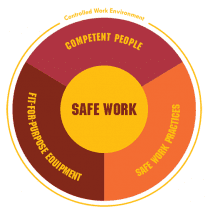

To help develop safe systems of work to manage risk, four facets of the workplace need to be considered:

- competency of workers (e.g. training, quality of supervision, experience)

- safe work practices (e.g. hazards and controls associated with the job are understood by workers, controls are practical and appropriate)

- fit-for-purpose equipment (e.g. condition, availability, quantity)

- controlled work environment (e.g. climate, adjacent work and traffic, safety culture)

Understanding the contributory factors and effectively managing risk allows individuals and duty holders to reassess risk when situations change.

Drilling safety risk management is an integral component of good management and governance. It is an iterative process, consisting of steps that enable continual improvement in decision making. Communication and consultation are important for each step of the process. The Australian Standard AS/NZS ISO 31000 Risk management – Principles and guidelines and the International Council on Mining and Metal’s Health and safety critical control management: good practice guide provides information on the risk management process.

ADDITIONAL CONSIDERATIONS

There are many ways to support the risk-based approach to manage health and safety in the workplace.

A better understanding of risks and ways to deal with them can be achieved through:

- undertaking risk assessments

- effective consultation with workers and others in industry (e.g. safety and health representatives, industry forums and associations)

- analysing previous incidents within the company and by safety alerts provided by regulators – learn from other’s experience, report your own

- considering relevant legislation • using resources and information

- codes of practice, guidelines, information sheets

- reputable relevant technical standards (e.g. Standards Australia)

- industry publications

- published scientific and technical literature (e.g. original equipment manufacturer manuals)

Developing a regular communication plan for both employees and clients helps to foster a safer work culture across businesses, as well was within, achieving safety awareness as well as compliance.

DRILLING SAFETY TOOLS

The Department has produced several resources to assist the drilling and exploration industry. The Mineral exploration drilling – code of practice was developed with industry input and was designed for ease of use and risk-based approach. It is a practical guide to assist in

the development and implementation of safe systems of work for all drilling operations.

The code of practice is supported by mineral exploration audits. The audits are structured so that operators can select those aspects relevant to the size and complexity of their operations, and the activities undertaken, and tailor the audit accordingly.

These and other resources such as the presentations on which this article is based, safety alerts, accident and incident reporting information can be accessed through the Department’s website at www.dmp.wa.gov. au/ResourcesSafety and subscription services.

Department of Mines and Petroleum inspectors Chris Gamble, Stuart Erskine and Dean Crouch give us the drill on exploration safety.

CHRIS GAMBLE

Chris has been working as a mines inspector for five years and has 23 years’ experience in the mining industry, working in areas from greenfields exploration to mineral processing.

STUART ERSKINE

Stuart has been conducting investigations with the Department of Mines as

an inspector since 2011.

As a diamond driller and qualified fitter he has previous experience working for both mining and drilling companies. Stuart conducts regular exploration drilling audits.

DEAN CROUCH

Dean has ten years’ experience in radiation, pharmacy and resource sector safety, and risk management. He has been with the Department as an inspector for two years.

Add Comment