The EMERST (Earth Moving Equipment Safety Roundtable) has published its’ updated guidelines that provide mining equipment designers interoperability protocols that assist in minimising and reducing vehicle interactions and collisions.

While the initial guidelines were first published in 2015, the new guidelines provide updated information for users and designers particularly in respect of high-level protocols developed by EMERST to manage residual interaction risks.

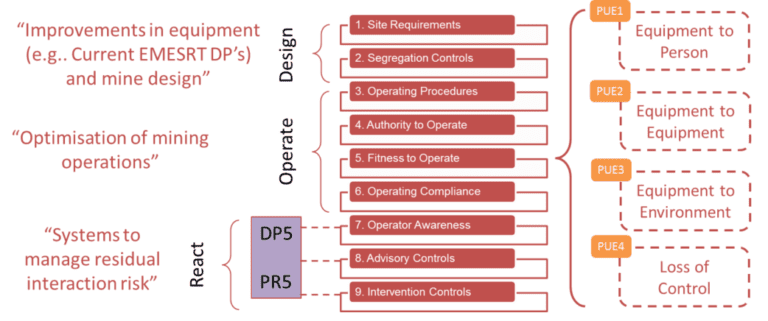

The objective of the guidelines is to prevent a person or equipment (machine or vehicle) causing a potential unwanted event (PUE) in the following four PUE categories resulting in injury or equipment damage:

- Equipment to person;

- Equipment to equipment;

- Equipment to the environment;

- Loss of control of equipment;

EMERST says that “The new version has been consulted on in several different industry forums, including at the recent International Council on Mining and Metals (ICMM) workshop held in London generating in-depth discussion amongst participants.”

The fundamental change is that the mining industry users have defined the functional needs for levels 7, 8 and 9 of the EMERST

Previously “designers were providing with the best intentions what they thought the design should address”, said Tony Egan, EMESRT Advisory Group member representing Glencore.”

“Since the release of version 1, PDS suppliers have used PR-5A as a key reference point in their designs. Recent discussions regarding the user functional changes in version 2 revisions have the industry talking”, said Jonathan Keyes, Sedna.

EMERST is a collaboration of some of the world’s largest miners to ensure standards of design meet the requirements of miners to reduce risk in mining. It has adopted a range of design philosophies that assist designers of mining equipment meet industry expectation in respect of risk.

EMESRT seeks to engage with key mining industry Original Equipment Manufacturers (OEMs) to advance the design of the equipment to improve safe operability and maintainability beyond Standards.

You can download the latest version of the EMERST Earth Moving Equipment Safety Round Table PR – 5A Vehicle Interaction Systems document here

Read more Mining Safety News

Add Comment