For 45 years, Haltec Equipment Australia has set the standard in off-highway, mining, and construction tyre management solutions and components. Haltec’s innovative approach to minimising downtime and developing superior quality, meticulously engineered valve systems to fit every equipment need have made it the unrivalled leader in manufacturing specialised tyre valve systems and automatic tyre pressure inflation solutions.

This precise and pioneering approach is behind every product that Haltec manufactures, from its rugged and reliable inflators to its Super Large Bore valve designs, the first of their kind in the world. As a manufacturer and worldwide distributor of tyre valves and accessories, Haltec calls upon decades of knowledge and experience working with mining companies to design and engineer purpose-built solutions to the real-world challenges that they face.

Safety net tightens for resources workers

One of those key challenges is developing solutions that are not only faster and stronger, but also safer, for the millions of mining workers who use Haltec parts and equipment to power the global logistics and distribution industry every day.

For Haltec, the relentless pursuit of safer ways of doing things – especially in industries like mining which rely on heavy-duty equipment to get high-risk work done – isn’t just a selling point: it’s an obligation.

Operators in the mining space have for decades grappled with the many risks involved with high volume inflation, including tyre fires and explosions that both destroy essential equipment and kill or seriously injure workers.

Haltec has developed a world-class range of tyre inflators and valves targeting this major risk area without compromising on productivity, efficiency or downtime. Because when it comes to high volume inflation, the right equipment is crucial to keep workers – and the business revenue their work generates – safe.

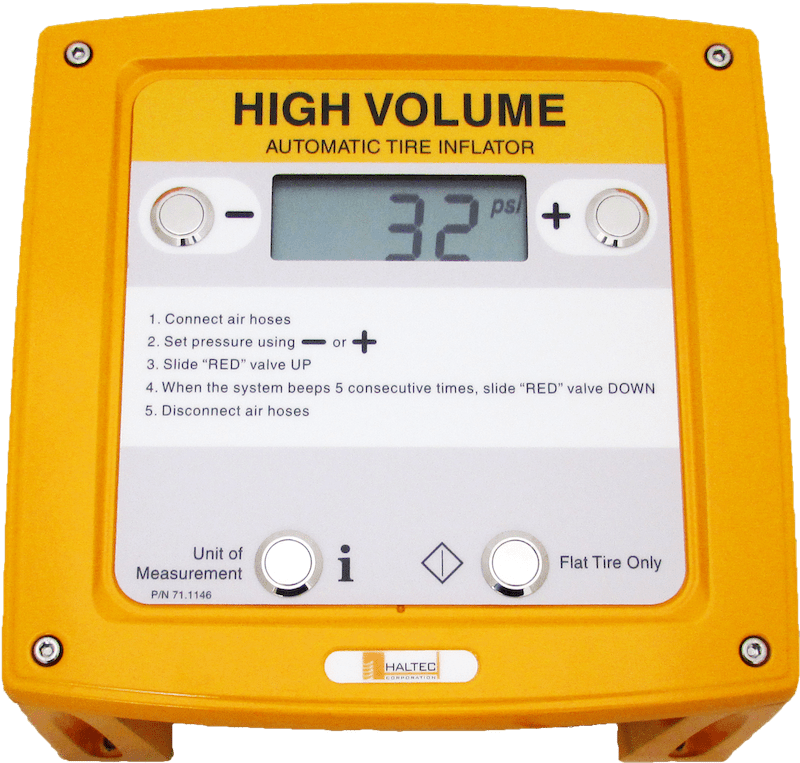

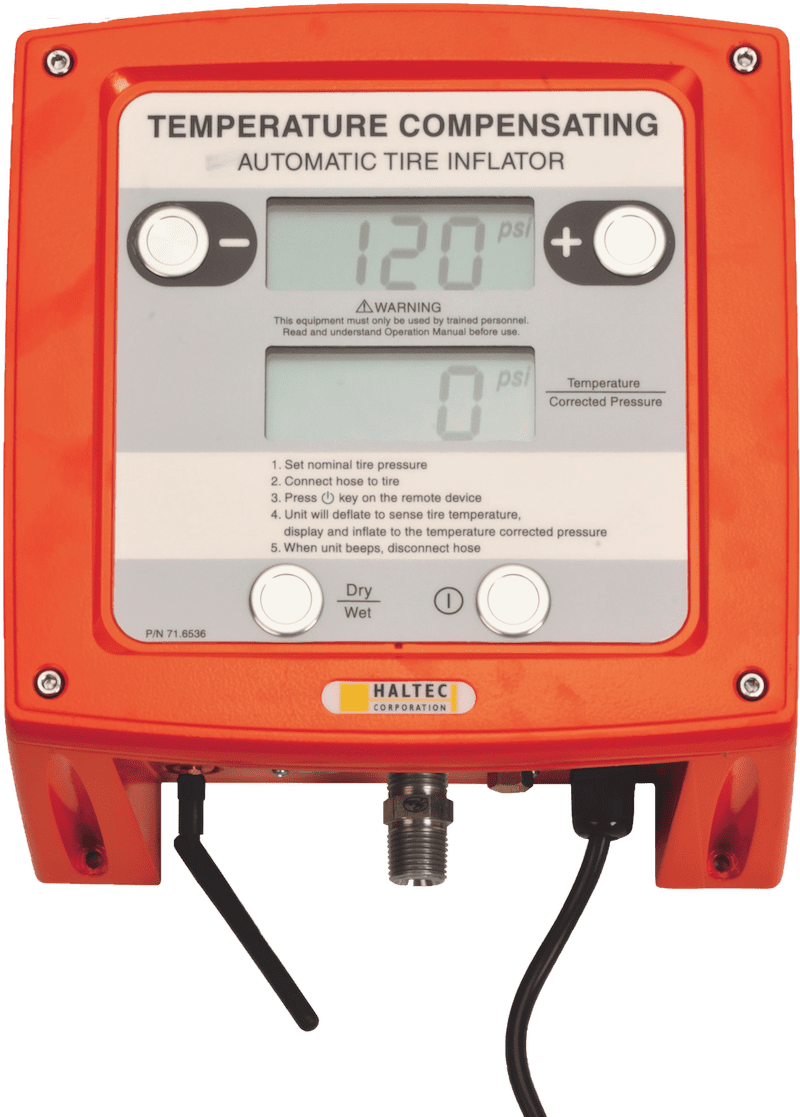

Take Haltec’s Automatic Tyre Inflators, which effectively eliminate the risks to workers using inflation devices by keeping them a safe distance from the tyres and equipment. The worker can stay outside of the blast zone while the wirelessly operated device automatically inflates or deflates to target PSI. With die cast aluminium housing providing the strongest protection and durability against weather and abuse, all systems can be programmed to specific PSI parameters to enable companies to seamlessly manage consistent and accurate tire inflation.

The inflation system is accurate to 0.5% FS, entirely remotely controlled, and wirelessly transmits and receives gauged and corrected tyre pressures via bluetooth, ZigBee or PC hardwiring.

Another popular safety device for keeping workers clear of the blast zone is the long inflator hose. At 20 feet long, the hose is equipped with a shut-off valve which enables the operator to stop inflation for proper, safe tyre inspection. Like all Haltec products, the long inflator hose is made to fit a range of equipment for different applications, with three additional unions to adapt to different sizes.

Haltec’s tire management system adds further value by enabling wireless, real-time collection and monitoring of tire inspection and inflation data. Using bluetooth-enabled devices and a web-based platform which serves data and insights in real-time, fleet managers can protect tire and rim assemblies from damage by inconsistent hardware and increase labour efficiency by more than 50%.

Further information for the best specialised tyre valve systems and automatic tyre pressure inflation solutions. Call Estry 07 3376 4155 or visit website.

Read more Mining Safety News

Add Comment