[hr]Darren Brady analyses real time, tube bundle and onsite ultra fast gas chromatograph systems and outlines advantages and disadvantages of each.[hr]

The underground mining industry in Queensland, Australia is internationally recognised as having the best mine gas monitoring systems. These systems are the result of nearly 20 years of ongoing development and follow recommendations from inquiries into explosions at underground coal mines in Queensland and subsequent changes to mining legislation.

The underground mining industry in Queensland, Australia is internationally recognised as having the best mine gas monitoring systems. These systems are the result of nearly 20 years of ongoing development and follow recommendations from inquiries into explosions at underground coal mines in Queensland and subsequent changes to mining legislation.

Each underground coal mine in Queensland utilises real time (telemetric), tube bundle and onsite ultrafast gas chromatographs (GC) to meet their gas monitoring requirements. The industry has realised that all three techniques are necessary for effective monitoring of the mine’s atmosphere. Each technique has advantages and disadvantages which must be known to those using the systems and those using the results to interpret the status of the underground environment.

Monitoring on its own will never prevent a mine fire or put it out if it starts. What it does offer is a means of identifying a problem early and subsequently an opportunity to take appropriate controlling actions. The earlier a problem is identified the better the chance of successfully dealing with the problem. The best chance of getting an early warning is by continual monitoring.

The successful application of mine monitoring systems requires the setting of appropriate alarms that trigger effective remedial actions. The mine must also implement effective maintenance and calibration procedures to ensure reliable ongoing operation of the mine gas monitoring systems if they rely on them for this early warning or in fact use results to assess any control measures they might implement during an event.

Monitoring Techniques

Real Time Monitoring

Real time sensor systems (telemetric systems) are ideal for telling us what is happening now. The sensors must be located where the gas needs to be measured, and the measurement signal is sent to the surface. This means having multiple sensors underground, and that these sensors are exposed to the harsh underground environment which is not ideal for precise analytical measurements. This is not really a major problem as these systems are used to detect step changes, such as the onset of a fire, a sudden increase in a seam gas in the general body or reduction in oxygen. They offer real time warning and are the best system for identifying a sudden event such as a belt fire. The situation is reported when it happens. Generally, sensors included are methane, carbon monoxide, carbon dioxide, and oxygen.

These types of sensors employed underground tend to have limited measuring ranges: carbon monoxide is often only capable of being measured up to 50 ppm, methane to 5 % and carbon dioxide to several percent. This range is fine while no problems exist, and indeed to alert the onset of a problem. But if a fire or other major incident involving generated gases occurs, these sensors may quickly reach full scale and be unable to return a true indication of the concentrations.

Due to the environment these sensors are in and their characteristics, they are not as useful for long term trending as the other techniques. Most of these sensors require the presence of oxygen to work and are therefore unsuitable for monitoring areas of low oxygen concentration such as sealed or non-ventilated goaves.

As each individual sensor needs to be calibrated regularly (at least monthly) they are not suited to being located for long term monitoring in inaccessible areas such as the goaf.

Some of these sensors also suffer from cross sensitivities, as the reactions they rely on to give a response can be common to other gases found underground, such as carbon monoxide sensors being cross sensitive to hydrogen sulphide and hydrogen.

In the case of an explosion it is likely that the real time monitoring system will be rendered inoperable, requiring other techniques for the determination of the status of the underground environment.

Part 7 of Queensland’s Coal Mining Safety and Health Regulation (2001) outlines the requirement for mines to have a gas monitoring system providing continuous monitoring of methane, carbon monoxide, carbon dioxide and oxygen at stated locations. The requirement for continuous monitoring as opposed to continual, which was previously stated, infers the requirement for a real time system, making this the only technique referenced in the legislation.

[pullQuote]“A good tube bundle system will include monitoring of the vacuum pressure in each of the tubes, so following an explosion this data can be used to determine whether a tube has been compromised or not.”[/pullQuote]Tube Bundle

Tube bundle systems draw gas samples from designated sampling locations underground to the surface through plastic tubes using vacuum pumps and analysed sequentially using infrared and paramagnetic techniques. Gases measured are carbon monoxide, carbon dioxide, methane and oxygen.

Tube bundle systems draw gas samples from designated sampling locations underground to the surface through plastic tubes using vacuum pumps and analysed sequentially using infrared and paramagnetic techniques. Gases measured are carbon monoxide, carbon dioxide, methane and oxygen.

Because the analysers are on the surface, tube can be located in the goaf, as once positioned there is no requirement to access the end sampling point (although sample filters and water traps located out bye will require maintenance).

Tube bundle systems are suited to long term trending (provided the system is suitably maintained). Very good analytical equipment is available and can be housed in dedicated air conditioned rooms on the surface with the samples dried and passed through particulate filters prior to entering the analyser.

Generally systems are set up to measure oxygen, carbon monoxide, carbon dioxide and methane. Given their ability to measure carbon monoxide down to 1 ppm; the long term stability of these analysers and the frequent sampling; this technique is best for long term trending of carbon monoxide, and carbon monoxide make, to identify a spontaneous combustion event. With respect to measuring range, it is normally only carbon monoxide that presents problems, with most systems capable of measuring to only 1000 ppm.

Because methane and oxygen concentrations can be measured over all expected concentrations ranges, this technique is the best for automated monitoring of explosibility of an area so long as a fire or heating doesn’t exist. This technique is best for monitoring explosibility during a routine sealing operation and for the early onset of any spontaneous combustion event.

To get this improved stability and analytical capability, the immediate availability of the results is sacrificed. The samples need to be drawn to the surface prior to being analysed, meaning the data being generated can be from samples collected from over an hour before. There is only one bank of analysers, so only one sample is analysed at a time. Depending on the number of tubes in the system and the programmed sampling sequence, each point may only be sampled once every thirty to sixty minutes. Add this to the time taken to draw the sample from underground, which may be as long as an hour and it is obvious this technique is not suitable for the instantaneous detection of an incident such as a fire.

To minimise delay time in sample analysis, a sample can be drawn to the surface by purging pumps that just vent the sampled gas to atmosphere. As multiple points are drawn through these purging pumps it is important to balance the flows of each of the tubes to ensure that each of the tubes is being purged and not just the tube with the least resistance.

Because the analysers in these systems rely on infrared absorbance and paramagnetic attraction, the gas matrix is not important, making this technique suitable for the analysis of gases from oxygen-depleted areas such as the goaf. What must be remembered is that the measurement of oxygen using paramagnetic analysers is flow rate-dependent and the flow from each tube must be balanced to be the same, including any calibration gases used. Otherwise it is possible that two locations could in fact have the same oxygen concentration, but because of more resistance in one of the tubes, the flow through the analyser is at a lower flow rate and, as such, results in a lower reading than a location with the same concentration but flowing through the instrument at a faster rate.

Too often the maintenance of the tubes is overlooked and the monthly leak testing identified in Australian Standard “AS2290.3 Electrical equipment for coal mines – Maintenance and overhaul Part 3: Maintenance of gas detecting and monitoring equipment.” is not performed or not done as stated by the standard. If maintenance follows the method outlined in the standard, it is not only possible to confirm that no leaks exist but also determine an approximate time taken for a sample to reach the surface. The knowledge of the draw times of each tube is critical to adequately assess what is happening and how long ago it actually happened in an emergency situation.

In the event of a mine explosion the tube bundle monitoring system may still appear to be functional but the location from which tubes are sampling may not be the same, due to damage to the tubes. A good tube bundle system will include monitoring of the vacuum pressure in each of the tubes, so following an explosion this data can be used to determine whether a tube has been compromised or not. It is also useful during routine operation for identifying increased restriction or sudden leakage in a tube, both of which can compromise the operation of the system.

If the tubes are damaged and not providing any valuable information, it may be possible to make use of boreholes and connect new tubes to locations of interest as the surface equipment will still be operational (flame arrestors are installed at each end of the sampling tubes).

Another major advantage of the tube bundle system is that it draws the sample to the surface and any locations requiring further analysis such as GC don’t require any additional trips underground to collect samples. This is particularly advantageous in emergency situations when personnel may have been withdrawn from the mine and re-entry is prohibited.

Gas Chromatography

Gas chromatography, with regard to gas analysis, involves the separation of all sample components followed by their measurement on relatively non-specific detectors. Specificity is obtained by virtue of the separation process rather than detection.

The use of a GC expands analytical capabilities to include gases crucial in the interpretation of spontaneous combustion events, particularly ethylene and hydrogen. The GC provides a complete analysis of the gases expected underground and is the only one of the three techniques capable of measuring hydrogen, nitrogen, ethylene and ethane. Determination of nitrogen is particularly important for determining oxygen deficiency in some spontaneous combustion indicating ratios.

Similar to the tube bundle, problems exist with bringing the samples to the GC. The significance of time delays in getting results is dependent on what the results are being used for. GC is not going to be suitable for detection of a belt fire because of the time delay between collection of the sample and analysis, but the delay is acceptable for confirmation of other results or for evidence and trending of spontaneous combustion indicators.

The GC is not the best analytical technique for low concentrations of carbon monoxide, therefore this technique is not the preferred method for determination of carbon monoxide makes nor low general body concentrations.

However, during a significant spontaneous combustion event, fire, or following an explosion, it is the only technique that will allow us to make an accurate determination of the explosibility of the underground environment.

Like the tube bundle system, the gas matrix of the sample does not affect GC analysis. So long as appropriate calibration gases are available, this technique is capable of measuring gases at any concentration above their detection limit. This eliminates the problems seen with the other techniques, particularly for carbon monoxide concentrations greater than 1000 ppm.

The ultrafast gas chromatographs in use in Queensland mines allow the analysis of most of the components expected underground in approximately 2 minutes. Since their introduction the number of routine samples analysed has increased significantly allowing the mine to build comprehensive background knowledge of the normal background composition of particular areas underground. This increased sampling and analysis regime has also increased the chances of identifying any deviation from what is normal and allows early intervention to deal with any problems identified.

This increased speed of analysis is invaluable during emergency situations, particularly when assessing the safety of the underground atmosphere for re-entry or during re-entry by mines rescue teams. In these cases what makes this assessment more effective is that GC is onsite and can be operated by mine personnel. There is no delay in determining the status underground while waiting for external providers to arrive or transporting samples away from site for laboratory analysis.

Comparison of Techniques

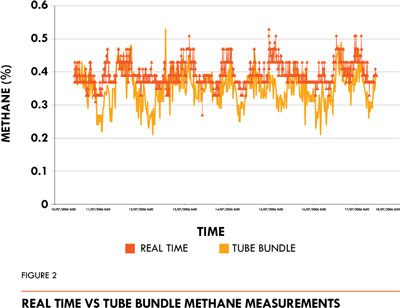

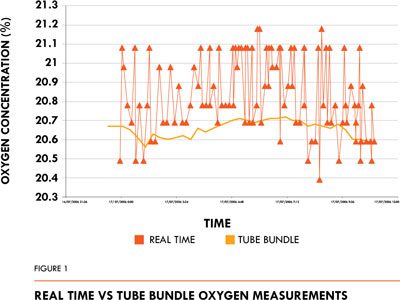

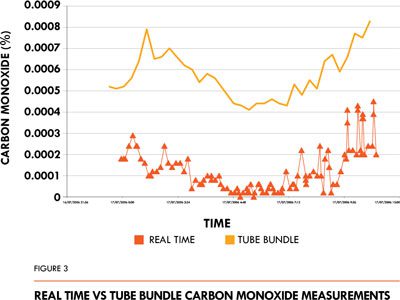

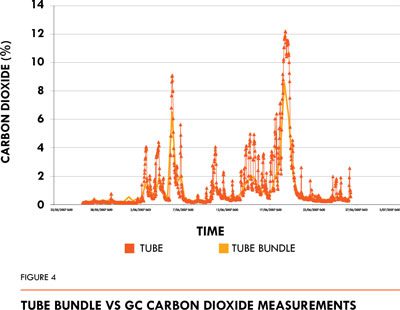

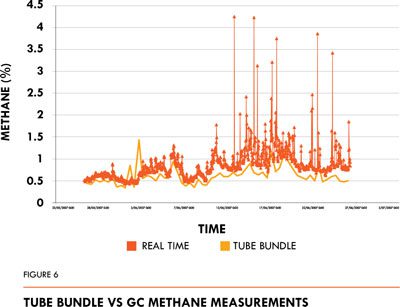

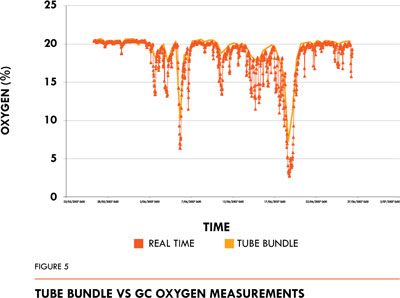

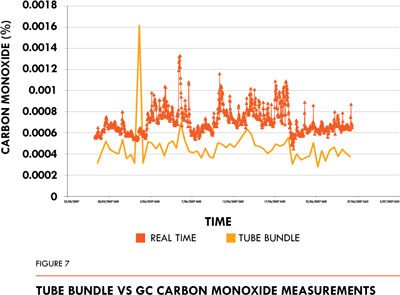

Comparison of results obtained at the same monitoring location using the different techniques are shown in Figures 1-7.

It can be seen in Figure 1, that oxygen measurements collected over 1 day showed much less variation in measurements made using the tube bundle than for the real time sensor which regularly varied by more than 0.3 % (absolute) between measurements. These variations make calculation of oxygen deficiencies used in ratios used for indicating /assessing spontaneous combustion, unreliable.

The methane results collected over 1 week in Figure 2 show good correlation in the magnitude of methane and reasonable agreement with trends between the two techniques. Although the absolute carbon monoxide concentrations measured over 1 day in Figure 3 were different, the trend over the 24 hours was the same for the two techniques. This difference may be as a result of a difference in calibration between the two techniques or as a result of sensor drift (most likely the real time).

Slight differences in absolute concentrations are evident and the difference in the amount of data collected by the techniques is significant, however the tube bundle data and GC data (Figures 4-7) show very good agreement over a one month period, reflecting increasing and decreasing trends. The difference in absolute concentration seen in Figure 7 could be a result of a difference in calibration gases used to set the instrument’s response.

When differences exist in the concentrations measured using the different techniques it can complicate the application of preset trigger levels. It also means that data for trends should only be generated by one technique and not an accumulation of results. When trends from different techniques are viewed they should indicate the same pattern. Often these measurement differences are related to the techniques themselves but some of the issues can be removed if calibration gases used for each technique are compared prior to being used to set instrument response.

Another strong point of real time sensors and tube bundle monitoring is that the monitoring points are at fixed locations, resulting in consistent automated sampling/measurement. When samples are collected underground for

subsequent GC analysis, variations in results and trends can often be attributed to not collecting samples from exactly the same locations, or poor sampling techniques.

Gas chromatography is the only one of the techniques that actually measures nitrogen. As mentioned, nitrogen is included in some ratios used to indicate spontaneous combustion. These ratios are still calculated from measurements made from the other techniques but when nitrogen values are required, the nitrogen concentration is assumed to be the balance remaining and calculated by summing the measured components and subtracting from 100. This presents obvious problems with the reliability of such calculations and in critical situations, calculation of these ratios should be done using GC results.

It is usual practice to confirm any abnormal results with one of the other techniques so prior to the need for any such comparison knowledge of how the mine’s own individual systems compare is required.

ASSESSMENT OF FLAMMABILITY

The need to perform a complete analysis by GC of atmospheres generated during coal fires or heatings is not only critical but the only option to obtain an accurate assessment of the flammability status of the underground environment.

Failure to do so can lead to wrongly assessing the atmosphere to be inert, when in fact it could be explosive or fuel rich, due to the generation of percent levels of carbon monoxide and hydrogen during mine fires. The presence of per cent levels of these gases not only adds to the percentage of combustible gases present but also has a major influence in the lowering of the oxygen nose point (the lowest oxygen concentration at which an explosion can occur).

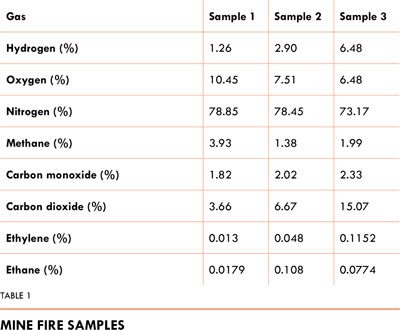

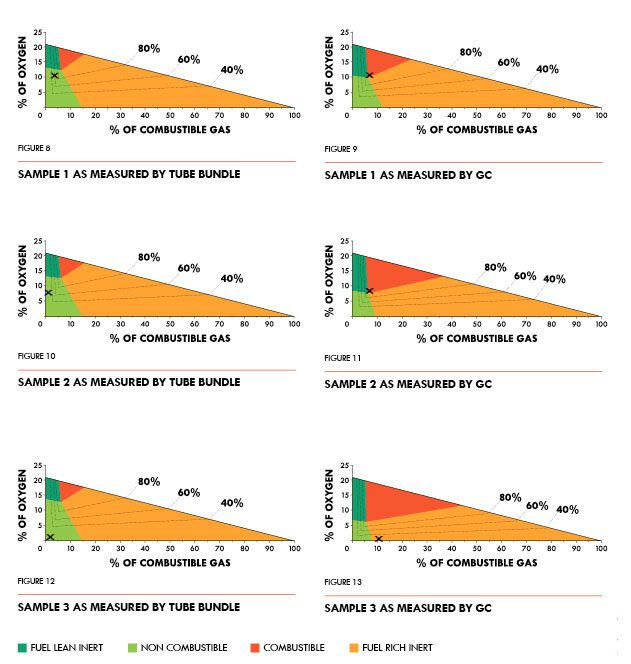

Figures 8 to 13 are examples of explosibility diagrams generated by GC analysis and tube bundle analysis of the same gas mix coming from heatings and mine fires. The composition of these samples is listed in Table 1.

[pullQuote]“As beneficial as they are, it must be remembered that monitoring systems on their own are not going to provide a successful solution to gas monitoring.”[/pullQuote]

Because the tube bundle analysis does not include hydrogen, and only includes up to 1000 ppm carbon monoxide, the percentage of combustible gas is underestimated and the calculation of the combustible (explosive) zone is incorrect. In a fire or heating situation, without the GC analysis an assessment of the flammability of the atmosphere underground is likely to be unreliable and can indicate that the atmosphere is inert when in reality it is explosive.

Figures 8 and 10 represent explosibility diagrams generated using results from tube bundle analysis during advanced spontaneous combustion events. If tube bundle results were used in isolation without consideration to the presence of hydrogen or concentrations greater than 1000 ppm of carbon monoxide, then the atmosphere could be assessed as being inert and rescue/fire fighting teams sent into the mine to deal with the situation. GC analysis of the same samples shows the atmosphere to be explosive (Figures 9 and 11) and considering the intensity of the spontaneous combustion, an ignition source is likely to be present.

Figures 12 and 13 represent a sample collected from an advanced mine fire. In this case the explosibility diagram from the tube bundle data shows the atmosphere to be non combustible. This would mean that from this data only and with no consideration to the presence of hydrogen or carbon monoxide concentrations greater than 1000 ppm, it would appear that it was safe to re-ventilate the area as there was not enough fuel for an explosion. The explosibility diagram generated by the GC data shows that the atmosphere is actually fuel rich, and the addition of oxygen to the area could push the atmosphere through the explosive zone, again with a likely ignition source present.

These examples highlight the necessity to determine the explosibility of the underground atmosphere using gas chromatography.

TRIGGER ACTION RESPONSE PLANS (TARPS)

Mines determine gas levels that they think should not be exceeded. Often these numbers are based on historical data collected from the monitoring systems. To handle the large volumes of measurements made gas monitoring software has been developed that will automatically trigger a visual and audible alarm if one of the preset levels is exceeded. Alarm set points can be different for every sample point. These alarms activate what are known as Trigger Action Response Plans (TARPS) that have predetermined actions to follow. These actions have been formulated to ensure that appropriate actions are taken to ensure the safety of workers and maintain control of the mine.

Alarms can be generated from absolute concentrations, gas ratios or explosibility. They are most useful as an early warning, not as an alert to an emergency or a need to evacuate the mine. When alerted early enough the mine will have time to take remedial action to rectify the problem. Having continual automated gas monitoring provides the best chance for early detection.

The frequency and scope of monitoring is often included in the TARPS to ensure that the situation is not escalating or that the control measures are being effective. It must be noted that if inertisation is one of the control measures called for in the TARPS, any monitoring to determine the effectiveness of the control must be done from a location indicative of the affected area and not just at the point of entry of the inertisation gas, otherwise assessment of the situation may not be indicative of the true state.

SUMMARY & CONCLUSION

As beneficial as they are, it must be remembered that monitoring systems on their own are not going to provide a successful solution to gas monitoring. Success depends on systems, processes and training built around the hardware and the way these systems are used.

An effective gas monitoring system includes real time sensors, a tube bundle system and a gas chromatograph.

Each technique is addressing different hazards.

Each technique has strengths and weaknesses which must be known by those both operating them and using the generated results for interpretation.

Effective maintenance and calibration procedures are required to ensure reliable ongoing operation of mine monitoring systems.

Interpretation of data is best done looking at trends rather than one off samples. Even if the situation is being underestimated, any increase in intensity should result in an increase in the trend although the rate of change may not match the increase in intensity.

Trends should only be based on data collected from the same technique.

There are likely to be differences between absolute measurements made using different techniques.

A true indication of the flammability of the mine atmosphere during a mine fire, heating or post explosion can only be determined by gas chromatograph analysis due to the high concentrations of carbon monoxide and hydrogen possible.

[hr]Profile Darren Brady

As a qualified Chemist and member of the Royal Australian Chemical Institute, Darren has specialised in mine gas analysis and interpretation for the past 21 years. He has been responsible for the development, support and functional implementation of gas monitoring systems with mines in Queensland, NSW and overseas. His knowledge and experience includes monitoring and interpretation of mine gases during emergency situations and practical experience in mine sealing operations. Darren has responded to mine explosions, fires and spontaneous combustion events. He has also developed and facilitated spontaneous combustion training, testing protocols and research. His extensive experience and knowledge has resulted in being invited to run workshops, lecture and deliver technical papers in India, China, the USA, the Netherlands, New Zealand and Australia.

[hr]References

Australian Standard (1990) AS2290.3 Electrical equipment for coal mines -Maintenance and overhaul Part 3: Maintenance of gas detecting and monitoring equipment.

[hr]This conference paper was originally published as Brady, D, The Role of Gas Monitoring in the Prevention and Treatment of Mine Fires in Aziz, N (ed), Coal 2008: Coal Operators’ Conference, University of Wollongong & the Australasian Institute of Mining and Metallurgy, 2008, 202-208.

The Coal Mining Safety and Health Regulation 2001 Reprint No. 2C, 2007 the Office of the (Queensland Parliamentary Counsel).

Add Comment