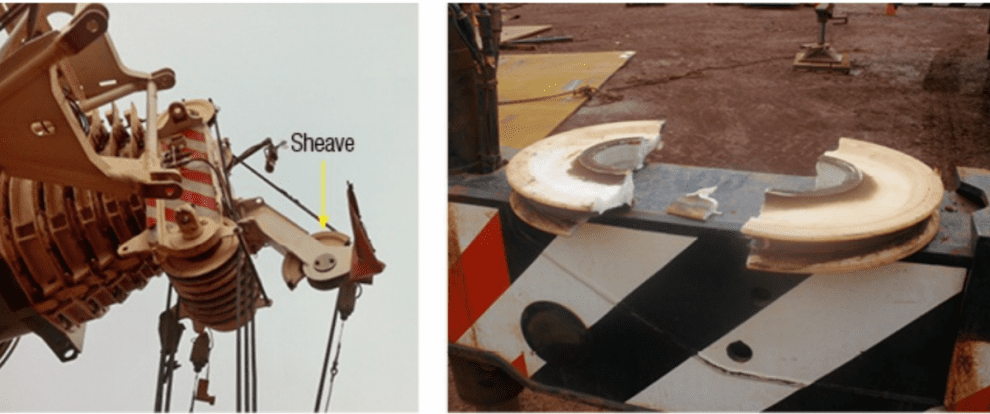

A rigger was narrowly missed by a falling crane head sheave, prompting a Department of Mines and Petroleum Significant Incident Report.

In July 2014, a mobile crane at a mine site was being used to unload a truck, as the crane started to slew, the nylon head sheave (rooster sheave) weighing about two kilograms, catastrophically failed.

According to the report, part of the sheave fell around 10 metres to the ground, narrowly missing a rigger working in the exclusion zone below.

“When the sheave was inspected later, it appeared to have been damaged prior to the lift. The weight of the load was within the crane’s safe limit. There was no side loading to the boom head sheave during the lift,” the report said.

The report outlined a contributory cause of the incident to be a failure to identify the damage to the sheave in the daily pre-start inspection by workers.

The DMP recommended actions relating to design, manufacture, import or supply requirements, records and inspections, operation and maintenance, and incident reporting.

“Competent persons who are in charge of mobile cranes should ensure: crane maintenance records are checked and cranes are inspected for defects before entering site crane inspection programs are reviewed and revised to include inspection and assessment of sheaves,” the report said.

See the full list of recommendations here.

Image – Right: Half of the failed sheave for the auxiliary hook remained in place. Left. Sheave sections recovered after the incident.

Terrible ! What’s more disturbing is the mental genius who wrote the report / recommendations. They should be charged with grammatical bastardry !

Chris Marshall

Fuck me looks like the up keep is priority with this mob

Dick Brennan

Andrew Timbrell