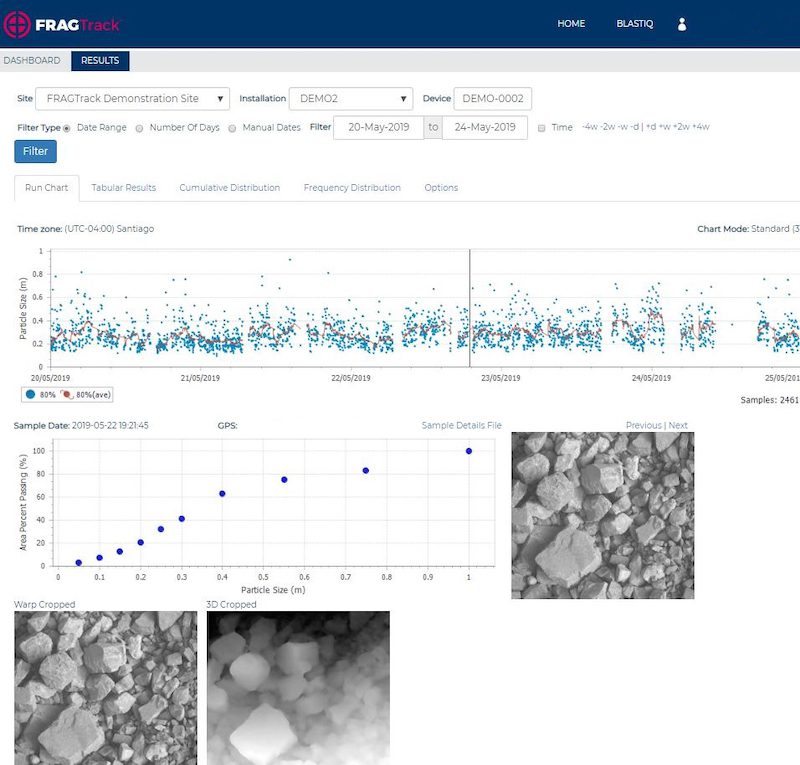

Optimising drill and blast performance with high tech tools just took another step forward. Orica (ASX: ORI), the world’s largest manufacturer of commercial explosives and innovative blasting systems, today announced the release of its new automated rock sizing measurement technology, FRAGTrack™.

The automated fragmentation measurement device, delivered as part of Orica’s BlastIQ™ Digital Blast Optimisation Platform suite, captures real-time fragmentation measurement data for optimising drill and blast operations; improving downstream unit productivity and tracking of operational performance.

Orica Vice President – Digital Solutions, Raj Mathiravedu said: “Systematic and automated measurement and analysis of blast fragmentation provides a basis for continuous improvement. Rock size distribution or fragmentation is a critical measure of tracking daily drill and blast performance, optimisation of blasting, loading and haulage, and maximising throughput of material during the processing cycle.”

FRAGTrack™ delivers accurate and reliable fragmentation measurements on both face-shovels and conveyors. The greater sampling frequency, enabled by the fully autonomous system, provides superior insights, allowing for visualisation and comparative analysis of multiple sample data sets – Empowering rapid and improved decision making for customers. It also delivers enhanced safety benefits through the removal of manual sampling methods on bench, keeping workers away from high-risk operational areas

READ RELATED CONTENT

- Sandvik mining releases surface hammer drill rig

- Whitehaven blasted for less than competent blast

- New performance standard for diesel engines

The system uses binocular cameras and an innovative proprietary hybrid 2D/3D image processing algorithm, overcoming the shortcomings of standard methods which usually apply them independently and lack accuracy. Specifically designed for durability in the harshest of mine operating environments, the hardware can handle temperatures ranging from below minus 30to above 45 degrees celsius, across a range of rock types and hardness levels.

Mathiravedu continues, “FRAGTrack is designed to improve productivity and optimise drill and blast through the integration of fragmentation data into the drill and blast planning and design processes. This creates an opportunity for our customers to significantly improve downstream outcomes.

“Driven by the needs of our customers to accurately assess blast outcomes including fragmentation, we continue to invest in developing intelligent and autonomous measurement systems that are easily integrated into existing mine ecosystems.

In addition to superior system reliability, a comprehensive training, support and Customer Success Program is delivered by Orica’s global network of technical services engineers and technology experts, ensuring customer’s realise blast optimisation and the associated downstream benefits.

Widely adopted across Orica’s technical services team today and built on more than 15 years of investment in research and development, the latest version of the technology to optimise drill and blast performance is now being made available for the first time to customers around the world.

Read more of Whats NEW in Mining

Add Comment