For decades, emergency services, mining, construction and industrial plant workers have used timber blocks to crib or stabilise heavy equipment and vehicles for rescue operations, repairs or maintenance. In fact, 99% of cribbing material being used today is wood. As an inexpensive, widely available material, it’s easy to see why.

But despite its popularity as a heavy load-bearing material, many engineers and OH & S professionals are speaking out with serious concerns over the fitness for purpose of timber blocks for cribbing.

Because when you’re working on heavy machinery, there’s no place for risk, and the consequences of workplace incidents can be painful, costly and at worst, fatal.

Focusing on the significant and now avoidable risks posed to workers—and the vehicles or equipment being lifted—workplace safety experts urge companies to consider a range of often hidden dangers of using timber cribbing blocks.

Wood is a highly variable material: the species and fibre density of each piece vary widely. Just because one timber block is known to bear a certain load doesn’t mean another of the same size or species will do the same, and as such, timber blocks are not load-rated.

These structural uncertainties alone are problematic, but to increase the danger to workers, each block’s structural integrity decreases with age and exposure to moisture or heat. Wood is highly permeable with water, becomes brittle when exposed to intense heat or prolonged sunlight, prone to splintering and can suffer permanent damage without showing signs of it on the surface.

It’s these all-to-often overlooked gaps in workplace safety that lead to devastating accidents. And, according to industry experts, it’s time to prioritise workplace and worker safety and make the switch to safer alternatives to timber blocks for cribbing.

Many mining, manufacturing and construction companies are eliminating these unnecessary risks with purpose-built cribbing equipment that helps to make maintenance work safer, faster and to the highest standards possible.

Haltec Equipment Australia, a worldwide distributor of world-class OEM parts, sells a range of cribbing, blocking and jacking equipment engineered for this exact purpose. Among its best-selling construction and mining safety equipment are lightweight, durable and impermeable cribbing and jacking tools with superior load-bearing capacity—minus the risks to workers.

Manufactured from 100% recycled plastic, these cribbing products manufactured by AME International Products are environmentally sound as well as oil, gas and chemical resistant, offering unmatched durability and strength. They come with a 50 year warranty against splitting, rot, fluid absorption, termites and mould, and are certified lab-tested as fit for purpose for supporting heavy machinery and vehicles while assembly, maintenance and repairs are carried out.

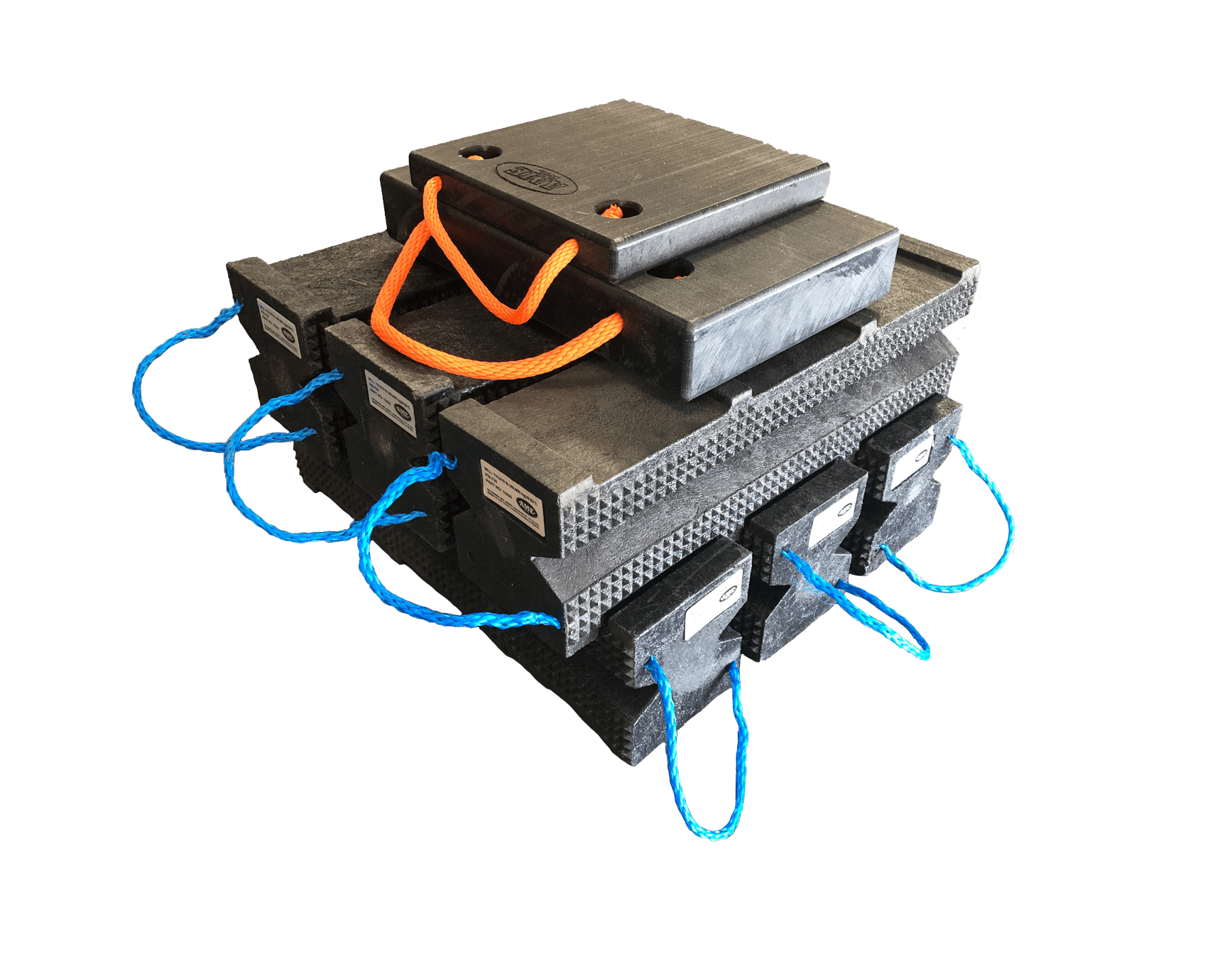

Take the Super Stacker Cribbing Kit, which includes stackable, interlocking cribbing blocks with a pyramid surface pattern for maximum slip resistance. Colour-coded lanyards allow workers to instantly identify the working load limit of each block by three categories: high-vis yellow for up to 20,000 kilograms, blue for up to 50,000 kilograms, and orange for up to 100,000 kilograms.

Unlike wooden cribbing blocks, AME’s high density polyethylene cribbing blocks are made with a consistent manufacturing process, a repeatable formula, and are subject to strict quality control and laboratory testing.

More information of AME cribbing equipments, click video

All this may make switching to plastic-engineered cribbing blocks seem like an offer companies can’t refuse. But while some workplace safety leaders are waking up to the imminent danger to workers and equipment associated with using timber for cribbing and jacking heavy machinery, regulators say the process isn’t happening fast enough.

If you’d like your company to be a leader in the pursuit of safer workplaces free from unnecessary risks to workers and machinery, there’s no time like the present. Get in touch with today to discuss the best cribbing equipment for your workplace. Call Estry 07 3376 4155 or visit Haltec.com.au.

A range of tyre-related safety equipment is also available through Haltec, including rigorously field-tested polyurethane wheel chocks for securing heavy machinery in place and heavy-duty steel tire-inflation cages. A catalogue of Haltec and AME products is available at https://haltec.com.au/catalogue/

Read more Mining Safety News

Add Comment