Safety systems and Site Assessment Profile help identify and mitigate risks that could improve your insurance premiums.

Risk management practices for fire safety in brownfield mines have often required extensive risk assessment sessions covering specific equipment such as conveyors, plant process areas and underground mining extensions.

Risk assessments of these different areas help establish the overall site risk and determine the insurance premiums. Among the variables that help to determine the insurance premiums from a fire safety perspective are:

- Mine construction

- Equipment assets

- Overall protection (detection and suppression)

- Exposure of people to fire

Mining losses arising from fires can have a significant financial impact over time. Insurance companies offer incentives and discounts for companies that go above and beyond basic legal requirements. For example, installing best practice fire detection and suppression systems in hazardous or hard to reach areas add an extra layer of protection to operations and is likely to reduce company premiums over time. This can be a great way to improve overall employee safety, protect equipment and still have significant savings with reduced premiums in the long run.

A report from Willis Towers Watson insurance company reveals that fires are still one of the main risks associated with mining activities, causing major mining loses in the last decade.

Major mining losses (2013-2019)

| Country | Cause | Loss |

| Australia | Fire in a benefaction plant | 120,000,000 |

| Chile | Conveyor fire | 60,000,000 |

| Australia | Underground longwall fire | 125,000,000 |

| Australia | Conveyor belt fire | Outstanding |

It is not uncommon that implementing a new system and technology can be cheaper in the long run than paying a higher insurance premium for being more exposed to risk without these extra layers of safety. The implementation of a best practice fire detection system, such as a fibre optic solution for mining will provide a lower total cost of ownership than any other conventional system that may not be able to cover long distances (km’s of conveyors) involved in a mining operation.

The first step in this direction requires conducting a Site Assessment Profile to help understand and determine your exposure to fire related incidents. These site assessments require a thorough understanding of potential sources of combustion, such as overheated equipment, product being stored or transported, flammable chemical storage, electrical systems, explosive area classifications, ventilation and so on.

It is important to have updated site assessments and conduct new ones from time to time as your site infrastructure ages or is modified to determine new areas of risk in your plant and mitigate the associated risks.

Mitigating risks through Site Assessment Profile (SAP)

Is your site equipped with safety systems that can detect and even prevent fires in risky areas? How well do you understand the existing fire detection and suppression systems for equipment areas? A common issue regarding this topic is that oftentimes the design of fire safety systems was developed at an earlier point in time and may not cater for any alterations or expansion of the mine. This scenario poses a major risk to many mining companies but through a site assessment profile risks can be mitigated.

In order to answer these questions and to complete a comprehensive fire risk assessment, a full site assessment profile (SAP) is recommended. The SAP will not only be an audit, but it will help analyse the mine’s existing fire safety systems suitability in the key materials handling and electrical systems both on the surface and underground. Some questions regarding the existing fire safety system that needs to be considered are below.

Site expansion:

- Is the existing detection equipment suitable for the plant changes?

- Is the existing fire suppression system (e.g., sprinklers or gas) large enough or suitable for the amended and/or plant expansion?

- Do our fire response procedures cater for these plant changes?

- Does the existing fire system reflect our harm minimisation approach for safety systems, including early real-time intelligent data gathering for the prevention of fire?

- Does the fire safety system meet our maintenance system approach for lower number of spares, and less frequent servicing?

Conveyors:

- What is the production duty cycle for each conveyor, and its cost?

- 24×7 production, 5 x 10 hours with weekly maintenance.

- Do you have a batch production system? If so, how many times a week are production runs made?

- What is the downtime cost for the conveyor?

- What are your site maintenance practices?

- Predictive, preventative, breakdown or a combination of each?

- What are the capabilities of your on-site staff including technical skills?

- Conveyor condition monitoring data gathering?

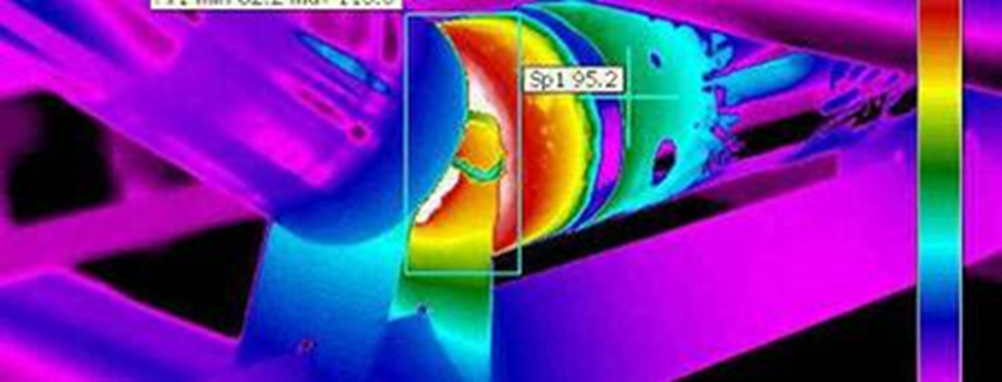

Overheated Conveyor Idler thermal image

Any electrical system associated with large conveyor’s (often 100’s of kW) power system is also a potential source of fire. Often these systems are more prone to fire due to overloading causing overheating or insulation failure.

Electrical system can include:

- Outdoor switchyards.

- Substation distribution switchgear (in a switch room or underground enclosures).

- Battery backup systems (for high voltage protection circuits, instrumentation and control, fire safety systems, lighting).

- Motor starting equipment including power electronics such as motor soft starters and variable speed drives.

The SAP process helps you understand the interconnection of the fire safety system to your plant’s operational and risk management strategy. By doing this it will ensure your fire safety system is not just a stand-alone alarm system, designed to just meet any compliance requirements, but it is integral to the optimisation of your plant’s productivity.

An effective system needs to be integrated to your plant’s operating system and provide both early emergency response capability but also valuable real time site condition monitoring information across all your key site assets.

The fibre optics technology allows you to perform these functions and is the most cost effective and flexible solution for the onerous operating conditions that exist on a mine site. The system unites the best of real time monitoring technology in a fully integrated and reliable system without regular maintenance as the fibre cable does it all.

Addressing those risks early with proper systems in place can help you not only prevent accidents and protect assets but achieve savings when it comes to your insurance premiums in the long run. Advanced Photonics Australia helps clients identify risk areas and recommend the best solution to improve safety and potentially reduce mining insurance premiums in the long run. Please get in touch if you would like to have more information about our Site Assessment Profile (SAP). You can also download our detailed SAP forms in our website www.apapl.com.au.

PROFILE

Advanced Photonics Australia

Advanced Photonics Australia provides cutting edge technology to safeguard your people and operations. The solutions can be applied to detect and prevent fires in mines, as well as other industry applications such as pipeline leakage detection, power cable and transmission line hotspot and load management.

Contact Advanced Photonics Australia for more information. Our experienced team will provide the right support on each product application and answer any questions you might have. Contact us via email at enquiries@apapl.com.au, phone +61 480 268 855 and visit our website www.apapl.com.au.

SOURCES

Rising Insurance Prices and Intensifying Risks: 5 D&O Priorities for 2021 – https://www.marsh.com/us/insights/research/five-directors-and-officers-priorities-for-2021.html

Mining Risk Review 2019 – Willis Towers Watson – www.willistowerswatson.com

> READ MORE Operational benefits of Fibre Optics Technology for fire detection

> READ MORE Fire detection for underground mining

Add Comment