An incident in which a supervisor was crushed between two vehicles has been put down to a lack of communication and failure to recognise risks, according to a report by the Department of Mines and Petroleum.

The December incident occurred while three workers and a supervisor inspected a damaged man-basket.

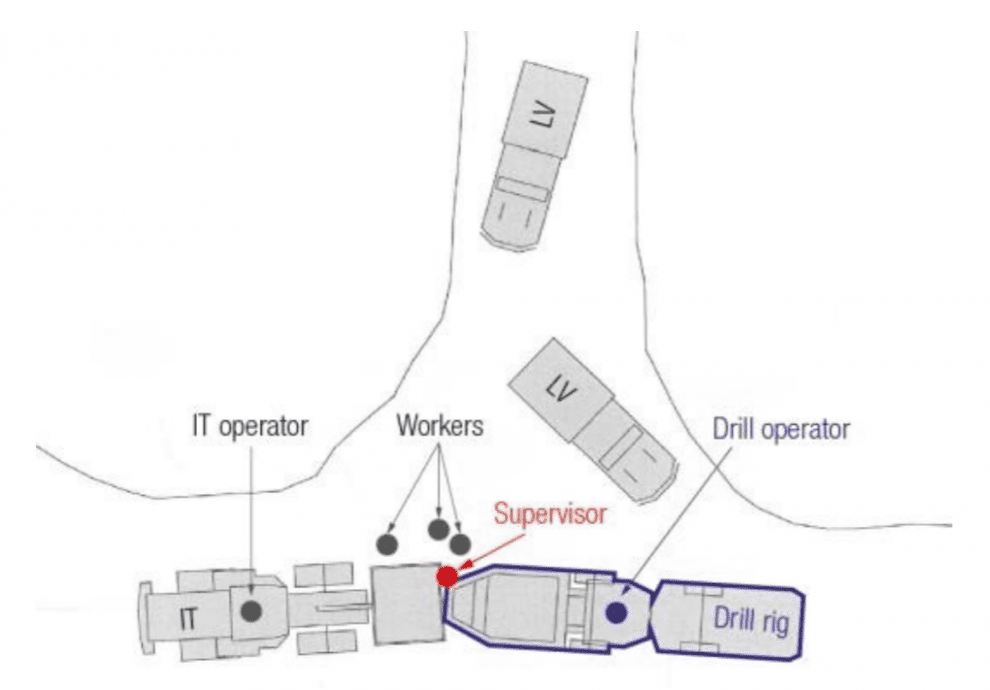

According to the report, an integrated tool carrier (IT) was parked in the underground main level access, while two light vehicles were park in an adjacent stockpile. All the parked vehicles had illuminated flashing beacons.

“At the same time, a long-hole drill rig was slowly tramming (horseshoe first) out of the level to the next drill location. While the drill operator was looking for an area to turn the rig around (to tram engine-first), the horseshoe made contact with the IT’s basket,” the DMP report said.

“The supervisor – who was facing the basket, taking photographs at the front of the IT – was pinned between the basket and the long-hole drill rig’s horseshoe and hydraulic hoses.

“It appears there was no attempt to communicate with the drill rig operator before his vehicle made contact with the IT.

“Colleagues provided first aid to the injured supervisor until the site ambulance arrived and brought him to the surface.”

The worker was hospitalised and underwent surgery for crush injuries to his lower abdomen.

The DMP noted the workers standing in close proximity to the IT, which was parked in a high traffic area, as a direct cause of the incident.

Contributory causes included a lack of effective communication between personnel, failure to recognise and manage the risks associated with working around mobile equipment, and the drill operator’s reduced field of view by tramming the long-hole drill rig horseshoe first.

“Mine operators are reminded of the importance of implementing and promoting positive communication protocols to maintain situational awareness developing, implementing and reviewing appropriate traffic management systems within all work places ensuring mobile plant operators are aware of workers and other mobile plant in their vicinity and potential line-of-fire risks promoting continuous awareness of the hazards associated with working in proximity to mobile plant,” DMP sai

Add Comment