Two workers were injured in a Western Australian underground mine after an arc flash incident.

An electrician and mechanical fitter were investigating water-overflow issues and found that a 90 kW submersible pump supplied from a 415 V motor control centre (MCC) had faulted, according to report by the Department of Mines and Petroleum.

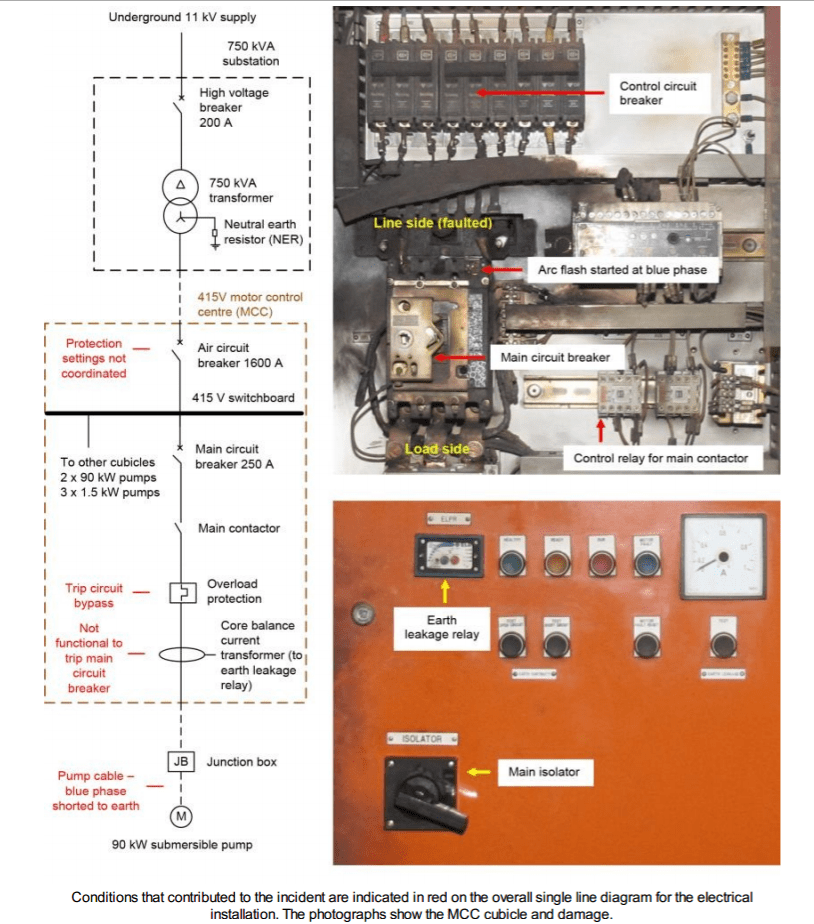

The electrician started investigating the pump control cubicle, and identified that a control relay contact had fused in the closed position and a control circuit breaker had tripped. The electrician replaced the control relay for the main contactor and, after examining the cubicle, reset the control circuit breaker.

The report said the electrician closed the cubicle door but without properly securing it, then he switched the main circuit breaker to the “ON” position. At that instant, there was an arc flash and blast, which blew open the door of the cubicle.

The electrician received first degree burns to his neck, face and ears, while the fitter received a minor facial injury.

The subsequent investigation revealed that the main circuit breaker had suffered a phase-to-phase arcing fault. The arcing fault started within the main circuit breaker terminal on the line side of the blue phase, and then transferred to a three-phase fault.

The DMP outlined the following as direct causes:

– The pump supply cable blue phase was shorted to earth (as confirmed by an insulation resistance test after the incident).

– The electrical circuit was not designed to automatically disconnect the main circuit breaker under an earth leakage or earth fault.

– The protection settings were not coordinated correctly, therefore the upstream air circuit breaker connected to the 415 V MCC busbars failed to operate. The high voltage circuit

breaker connected on the primary side of the 750 kVA transformer cleared the arc fault current of about 9.5 kA in more than 1 second.

ACTIONS REQUIRED

Principal employers and responsible persons are reminded of the importance of monitoring and reviewing electrical design and electrical installation compliance to ensure that they meet the Mines Safety and Inspection Regulations 1995. So far as reasonably practicable, the potential for arc flash should be minimised by using the hierarchy of control as a guide.

The following measures are recommended:

Elimination or substitution

– Where reasonably practicable, based on the fault levels of the electrical installation, consider remote switching of electrical equipment.

Engineering controls

– Ensure that electrical installations are designed, inspected, installed and tested according to Australian Standard AS/NZS 3000 Electrical installations (known as the Australian/New Zealand Wiring Rules) and are adequately protected against thermal overload and short circuit protection (earth and phase faults). Conduct protection coordination studies to provide the best possible fault clearance times to limit arc flash energy levels arising from a fault. Consider manufacturer’s recommendations when designing electrical installations to eliminate known hazards.

Administrative controls

– Ensure electrical drawings are updated and correctly reflect the installation.

– Consult electrical installation drawings as part of the risk assessment process to identify hazards and implement adequate control measures before undertaking maintenance tasks.

– Develop safe work procedures (SWPs) to safely conduct electrical maintenance tasks.

– For preventative maintenance systems: conduct preventative maintenance of electrical equipment based on manufacturer’s recommendations and guidelines and ensure the systems include periodic testing and verification of protective devices for their intended operation.

– Ensure faulty electrical equipment is not returned to service until fully investigated and adequately tested (e.g. offline insulation resistance test) for compliance. Ensure adequate levels of supervision and engineering assistance are provided for electrical work being conducted on site.

Personal protective equipment (PPE)

– Ensure adequate PPE (rated for arc flash) is worn when working on switchboards or distribution boards where there is the potential for arc flash.

Add Comment