A metal bar flew across a work area and pierced through heavy equipment.

Authorities recently investigated how a hydraulic porta pack propelled a rod with so much force it easily penetrated a machine.

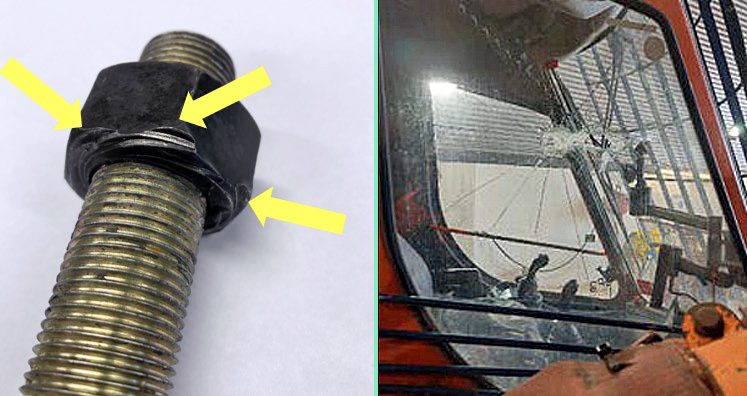

“A hydraulic porta pack was being used to pull a strut pin bush into position on a 777 truck, deck pivot … [and] during the task the rod has failed adjacent to one of the nuts and the rod has been propelled across the workshop – about [a] five metre distance and three metres above floor level,” the final incident alert said.

“The rod has penetrated the cab window of a Pantera drill parked adjacent and came to rest on the operator’s seat.”

Investigators concluded the employer failed to use the correct tools, puller rod rating and work procedure. They also found the risk assessment was inadequate, and there should have been more staff supervision and safety barriers.

“[There was a] less than adequate assessment of fit for purpose tooling (dolly, rod, hydraulic ram) [and a] failure to notify the supervisor when a change to equipment and the task was identified,” the alert said.

“[There was also] use of incorrectly rated puller rod (mild steel). The use of stepped task-specific dollies, which would have prevented misalignment of the dolly that caused the dead-ending against the pivot/chassis, were not available in the contractor’s workshop.”

They made the following recommendations:

- all contractors should complete site hazard identification and risk management training

- a correct dolly for the task should be made available at the contractor workshop when performing work

- mobile plant management should implement workshop inspections and review contractor workshop activities twice weekly

- meetings should be conducted with contractor management about improvements and to help supervisors with risk management controls and job tasking

- additional rated rods should be purchased and non-rated rods should be located in a controlled environment while, at the same time, checking storage during workshop inspections.

“When a change does occur appropriate actions must be taken by the worker and the supervisor to ensure that controls are implemented, to ensure the health and safety of workers – and to prevent equipment damage,” the alert said.

“Appropriate contractor management responsibilities include ensuring that contractors (and sub-contractors) are provided with competent supervision, hazard identification/risk management skills, fit for purpose tooling and approved procedures.”

Click here to read the full incident alert.

Related articles

Loss of concentration ends in fractured spine for coal worker

Employer fined after sinkhole swallows machinery

Catastrophic failure extensively damages truck

Blind spot tears roof off water truck cabin.

Add Comment