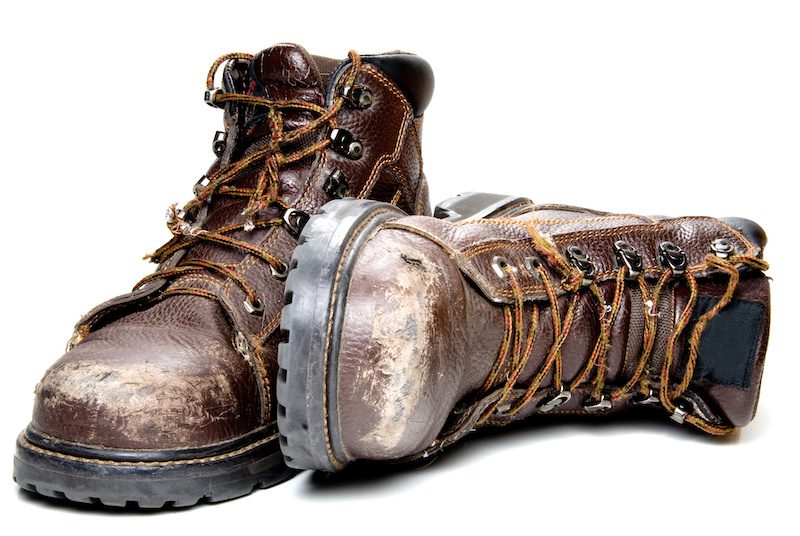

If you are joining the Australian mining industry or have been a long term miner you’ll know that a pair of mining work boots are a fundamental part of your safety kit and can either be your best friend or your worst enemy. We’ve assembled some tips and research on choosing the correct footwear for miners.

With shift times of 12 hours or more, mining industry personnel recognise that choosing the right safety boots is as important as getting good rest in your downtime. Poorly fitting mining work boots not only result in pain but can have significant effects on your long term wellbeing.

Extensive research undertaken from the Biomechanics Research Laboratory of the University of Wollongong has also shown that underground miners typically remain on their feet for extended periods of time throughout their working shifts. and that underground coal miners preferred a boot with a flexible shaft and a stiff sole because they perceived that it provided a good fit (length and width wise), good ankle support and was comfortable and easy to walk in.

With toe protection or steel-cap work boots required as core personal protective equipment for workers in all occupations where the risks of sustaining cutting and crushing injuries to the feet are no doubt high (Marr & Quine, 1993) So the obligation for companies to ensure workers use effective mining work boots is apparent.

Of course, choosing the correct footwear to mitigate injury from a range of hazards is a given. When choosing the correct footwear miners should consider exposure to relevant hazards including:

- contact with falling, rolling or cutting objects;

- penetration from the sole or upper shoe;

- contact with chemicals, molten metals and heat;

- slipping, tripping or falling.

Stability: Look for stability in the back two-thirds of the boot.

Cushioning: Make sure the boot has adequate cushioning if you are on your feet all day.

Strong heel counter: To secure the heel and reduce fatigue over the course of the day.

Flexibility of the boot at the toe joints: This will allow you to bend and walk easily throughout the day. Bending on uneven surfaces is common in mining so try and test the boot for this characteristic early

A removable liner so that you can adjust the cushioning in the boot or replace it when it ages.

Style can play an important role in boot selection – if you don’t like the style you’ll probably not wear it for long. There are typically six styles of work boots that miners may choose.

READ RELATED CONTENT

- Waterproof work boots | There’s a new boot in town

- More tips for choosing good mining boots

- Best work boots | A guide to selecting work boots

- Maternity workwear | Empowering women in mining

Mining work boot styles

Lace-up work boots

Over-the-ankle lace–up boots can provide protection for wearers from a range of hazards including burns, cuts and abrasions. The lace–up work boot provides a tight fit at the top making it less likely for objects to enter the boot during work. Lace-up boots have an advantage in that they allow a user to constantly adjust the fit of the boot to suit their comfort levels, however, some risks may be present from the trip hazards associated with laces that come undone.

AMSJ recommends that when selecting mining work boot, do so from manufacturers who not only comply with standards but select quality materials in the manufacturing process to ensure the boots are both durable and comfortable in the longer term. We would always remind miners to check with your site conditions as some sites do not allow lace-up boots under their footwear safety requirement.

Zip-sided work boots

Zip-sided mining work boots are easily put on and removed and have made many across the industry very happy. People with mobility issues such as stretching and bending may prefer this style of boots but once again, check with your site’s safety footwear program requirements

Ultimately the end games is to minimise heel pain, back pain, tired legs degenerative conditions such as arthritis. Zip sided boots can do all these if they are chosen and fitted correctly.

Non-slip shoes and boots

While many safety boots in mining and resources are water resistant, their may be a number of jobs where you are constantly walking on slippery surfaces. Boots can be made with differing friction coefficient in terms of slips…worth considering if you are likely to be in high slip areas.

Higher leg protection (most suitable in underground environments)

Underground workers traditionally wore rubber boots to minimise wet feet throughout the day. They offered some protection but generally not sufficient support and calf area protection. In most underground mining environments worker choose boots with:

- High-quality waterproof leather

- High abrasion resistance and tear strength

- Fully enclosed metatarsal protection

- Quick closure and simple release lacing systems that are adjustable for a personalised fit

- Full bellows tongue

- Arch support

- Extra cushioning to absorb shock with low-density midsoles

- Anti-bacterial, breathable and washable inners

- Cut and slip resistance, highly resistant to hydrolysis and microbial attack – heat resistant to 300?C – oil, acid & organic fat resistant

- Fitted shank for maximum torsional stability

- Electrical hazard resistant

- High joule impact resistant tow caps

- Compliance to: BS EN ISO 20345:2004

Safety Joggers/runners

Safety runners, safety joggers or safety shoes offer a range of protections and styles They are typically lightweight and offer increased protection over a traditional leather base show. Some mining sites will not allow you to use this type of safety footwear because it does not provide adequate heel and ankle protection. They may be perfect for lower risk office environments that sometimes enter work areas. Modern safety joggers offer users a balance between comfort and protection at lower risk workplaces.

Mid-cut 150 mm mining work boots

Without a doubt, mid-cut mining work boots are most popular across the mining industry. Most sites require this type of boot because it offers ankle protection and lower leg stability. They come in a range of options including waterproof, cut and penetration protection, self-cleaning treads, moisture absorbent liners, antibacterial liners. Look for Kevlar threads on critical high wear seams or otherwise, you’ll find the seams break in a short time.

Try most of all to ensure the mining work boots comply with AS/NZS 2210.3:2009, EN ISO 20345:2011 or ASTM F2413-11

Last words on choosing the correct footwear

Finally, don’t underestimate the value in your work boots. If you’re in them and on them for 12+ hour shifts, they can either be your best friend or your worst nightmare. Try not to scrimp and save on work boots. While it’s tempting to slip down the local hardware and pick up a pair that are cheap, you’ll probably find they’ll also be nasty. Take the time to get the right boots designed to mitigate against the hazards that you’re exposed to in your job…your feet and body will thank you in the long term.

References:

Improving Footwear for Underground Coal Miners Coal Services Health and Safety Trust (HST Project No. 20620) available online at https://www.coalservices.com.au/wp-content/uploads/2017/12/Improving-Footwear-for-Undergrond-Coal-Miners-Final-Report-HST-Project-No-20620.pdf

MARR, S. & QUINE, S. 1993. Shoe concerns and foot problems of wearers of safety footwear. Occupational Medicine, 43, 73-77.

Add Comment