The Global Mining Guidelines Group (GMG) has published the Guideline for Implementing Short Interval Control in Underground Mining Operations.

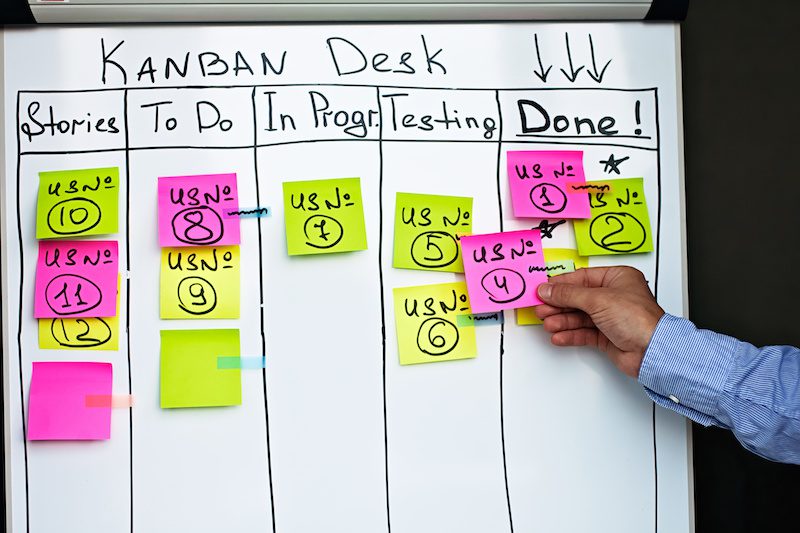

Short interval control (SIC) is a structured system in which data from mining processes are periodically reviewed and action is taken in response to them.

This new Global Mining Guidelines Group guideline provides a roadmap to increase the speed and likelihood of success during SIC implementation while avoiding common pitfalls. Specifically, the publication presents a conceptual model of what SIC could look like that includes an operational framework, detailed workflows, and an outline of data enablement at various levels of maturity.

SIC has only recently begun to be used in underground mining, although it has a long history in the manufacturing industry. One challenge in implementing SIC is tailoring it to the operation at hand because underground mining conditions can be unpredictable, but the guideline offers mining stakeholders a base of knowledge of how it can be applied.

Greg Sandblom, Operation and Business Technology Lead at Sudbury Integrated Nickel Operations, a Glencore Company, says the guideline “can provide a valuable reference to mining companies during all phases of Short Interval Control deployments at existing mines or new mine projects. It can effectively act as a checkpoint to validate that lessons learned and experience from leaders across the mining industry are applied to their implementations.”

READ RELATED CONTENT

- Underground mining vehicle gains traction in overseas markets

- Proximity detection framework on the table

- Virtual reality mine provides increased learning opportunities

Lisa Önnerlov, Development Engineer – Industrial Design at Boliden, confirms this potential application of the guideline for those already using a SIC system. “Even though we have been working with SIC for many years, we still have a lot to improve. We face challenges like refining the overall coordination and to take advantage of new technological possibilities and make it useful in reality. We hope that this guideline will be a tool for both benchmarking and as a common reference in collaboration with other mining companies working with SIC.”

SIC has the potential to increase productivity and lower costs. As Gordon Fellows, President of Fellows Mining and Digital Solutions, says, as the practice becomes more common, it will, in turn, become increasingly accessible: “Achieving the greatest benefit from SIC comes from monitoring and controlling the shortest interval, but results are possible even at lower levels of maturity and at lower cost. As technology evolves, it will make it simpler and less expensive to reach higher levels of maturity.”

One highlight of the process of developing the guideline, according to Liv Carroll, Senior Principal, Mining Transformation and Applied Intelligence at Accenture, has been the input from and cooperation between various stakeholders in the mining industry. Carroll says there has been “an effective collaboration between operators, service providers, consultants and technology specialists alongside the GMG team; our industry working as one for the benefit of all. In working together, we have drawn on a breadth of global and diverse experience to amalgamate leading practices into the guideline considering all levels of maturity and allowing for future evolution.”

Looking ahead, implementing SIC offers great potential for positive change in the industry because it facilitates better planning, quicker decisions, increased production, lower costs and creates a safer working environment. GMG Chair Michelle Ash says “I am very excited to see the publication of the SIC guideline because it is not only the culmination of a lot of work from many people, but also a fundamental building block for the transformation of our industry. I am looking forward to visiting mines post implementation and seeing the case studies that arise from their efforts.”

What is short interval control?

Short Interval Control (SIC) is a structured process for identifying and acting on opportunities to improve the effectiveness and efficiency of production. It may also interact with safety and quality processes.

It is essentially a factory-floor process that engages team members to review performance data three or four times within their shift to assess where they need to focus their efforts to improve performance.

SIC is very much a TQM or Kaizen type of process encouraging teams to work together to achieve regular, incremental improvements to the manufacturing process.

TQM and Kaizen processes often worked with delayed or historical data facilitate process improvements. Short interval control uses of real-time production data to guide instantaneous front-line decision making.

Teams are trained to collect, analyze, and react to this data in order to drive significant performance improvement from the factory floor or mine site. Through the use of the processes significant improvements in OEE (Overall Equipment Effectiveness) when effectively implementing SIC (e.g. a site with 60% OEE improving to 65% OEE in under three months and to 75% OEE within two years).

Successful implementation of SIC on mining sites may have the following benefits:

- Increased OEE (by focusing on immediate and relevant losses within the shift)

- Increased effectiveness (by utilizing high-quality data at its source to drive decision making)

- Fast pace of improvement (localized focus increases the pace of improvements)

- Improved employee engagement (teams gain significant control over how the line is run)

Read the Short Interval Control Guideline on the GMG site

Read more Mining Safety News

Add Comment