The NSW Resources Regulator has issued an alert to mines following a mine accident where a workbox falling from a loader in a metalliferous mine. The incident has highlighted the requirement for mines to ensure that workbox and other ancillary equipment fitted to loaders & tool carriers are compatible with lifting/engagement points on equipment.

According to the Regulator, a workbox detached and fell two metres from a loader. A mine worker who was in the workbox suffered a fractured lower leg and back injuries as a consequence of the falling workbox. The incident occurred on 2 December 2018.

Circumstances of the accident

Two engineering maintenance workers were tasked with installing a cable at the roof level using a loader and workbox in an underground metalliferous mine. The machine they were using was a wheel loader that had been converted to an integrated tool carrier.

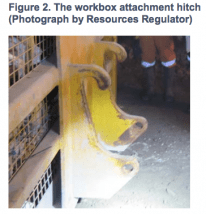

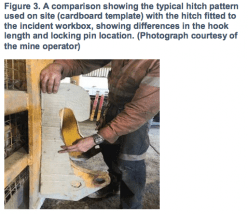

The workbox attachment assembly was not fully compatible with the attachment assembly on the loader. When the locking pins were disengaged, the attachment was able to swing, disengaging from the attachment hook.

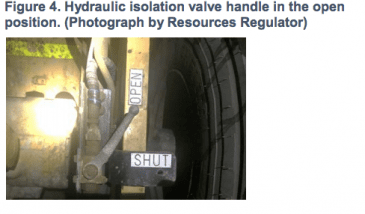

The hydraulic isolation valve was not engaged to stop the locking pin (that was holding the workbox) from disengaging during operation. The loader operator selected the workbox locking pin release switch. The locking pin disengaged causing the workbox to detach from the loader and fall to the ground.

Investigation outcomes

The NSW Resources Regulator attended site and conducted an assessment of the mine’s investigation into the incident and identified the following factors associated with the incident:

- The mine operator failed to identify and control the risk of the work box falling from the tool carrier if the locking pins were disengaged.

- The locking pin was not hydraulically isolated in line with operational procedures and the pre-start checklist.

- The switch panel layout presented a risk of incorrect switch selection.

Recommendations by the NSW Regulator to mines

The Regulator said that mine operators should review their safety management systems, particularly focusing on ensuring that:

- workbox attachment systems are fit-for-purpose with machine attachment systems

- change management arrangements for the modification and maintenance of workbox attachment systems are to be assessed in consultation with relevant equipment manufacturers or engineering specialists

- for any modified plant, mines should conduct thorough assessments to ensure compatibility with existing site equipment and attachments

- operational switches in mobile equipment are of an appropriate type, positioned and labelled appropriately to prevent inadvertent operation and consider additional barriers or protection of the locking pin release switch

- information, instruction and training are provided to and implemented by workers for the safe use of workboxes.

Link to the NSW Resources Regulator’s Alert

Latest stories 72-Year-old woman first to be jailed for breach of duty when a workers fell from forklift tynes raised to three metres.

Read more Mining Safety News

Add Comment