The Moura mine disaster of 1994 is a case study in the failure of organisational learning and emergency knowledge management, writes Judith Ann Chapman.

Just before midnight on 7 August 1994, the first of two explosions ripped through an underground coal mine at Moura in outback Queensland. Twenty-one miners were working there at the time. Ten managed to make their way through the dust and heat to the surface more than a mile away, but 11 did not.

The dangerous conditions frustrated all attempts to enter the mine and rescue any survivors or recover the victims. The mine was later sealed.

The cause of the initial explosion was never finally determined but was most likely triggered when a pocket of burning coal came into contact with combustible methane gas in a section known as panel 512. This had been the third disaster from underground explosions in the area – 13 miners died at nearby Kianga in 1975 and 12 at Moura mine disaster (Moura No. 4) in 1986.

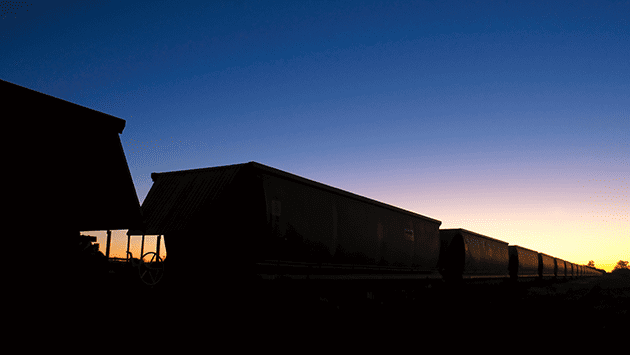

Work at Moura No. 2 started in 1970 and around 170 men were employed there. Long tunnels led to the coalface where continuous mining machines worked at depths reaching 265 meters. The coal was produced one panel at a time – when fully worked, each panel was sealed with brick and concrete to isolate it from the rest of the workings.

In all, 28 panels had been mined and sealed before work commenced on panel 512 in November 1993. In the first stage known as the advance, the pattern of access roads and solid coal pillars to support the roof was laid out to the extremities of the panel.

READ MORE RELATED CONTENT

- Australian Mining – A short history

- Remembering Wayne Fowlie – A roof fall claims a life

- Mine Safety concerns close century-old mine

Then in late April 1994 extraction continued into the second stage known as the retreat. This involved the stripping of pillars in alternate rows and by cutting more deeply into the floor. The method used during the retreat was different from that of previous panels where the roof was allowed to collapse behind the continuous miner. This time enough roof supports were left for the mined goaf area to remain open. This innovative design achieved the highest rate of production of any panel at Moura No. 2 but had the unintended consequence of allowing loose coal to accumulate around the columns and under the floor ramps.

There was also some localised roof falls during the retreat that might have concealed loose coal. The problem with loose coal is its potential exposure to oxygen in the air, which spontaneously starts a heating process. When very hot, the coal can trigger an explosion if combustible gases are present. Good ventilation was the main means of preventing the coal from heating but in this case, it apparently failed to do so.

Mine management had good reason to think that the risk was low. The new panel design meant that the mined areas would remain open: they could make sure cool air was circulated right through to the back of the panel and inspect the spaces relatively easily. They also felt safe in the knowledge that the retreat would begin and end within three or four months, well within the six-month incubation period. This view (an erroneous one as it turned out), that loose coal takes six months to heat when exposed to air, was longstanding, having passed from one generation of miners to the next, and originally based on experience in the coalfields of England and Wales. In a risk assessment after extraction in Panel 512 began, spontaneous combustion figured very low after machine operation, roof and rib falls and personal injury.

As it happened, ventilation was a constant headache for the shift supervisors and staff in this panel. On numerous occasions they found gas and hot air accumulating in certain areas and had to physically move brattices or open and shut regulators to redirect airflows. But generally, this only served to move the problem to another part of the goaf. An early attempt was made by one of the managers to track ventilation changes on a whiteboard in the site office on the surface, but it didn’t last. Looking back, this situation led the mining warden to state (Windridge, p.26):

“Overall, it seems that day to day ventilation problem solving, and operational, or accidental alterations to panel ventilation may have defeated the overall design intent regarding positive, controlled goaf ventilation and so increased the likelihood for spontaneous combustion … It seems likely that parts of the goaf may have been alternately starved of, and then supplied with, ventilating air; a most undesirable situation.”

“The subsequent enquiry, which lasted 40 days, revealed numerous instances of inadequate monitoring and evaluation in an organisation that otherwise appeared to be well-managed in accordance with the applicable mining regulations.”

By early August coal extraction in the panel was almost complete and a decision was made to seal it. Afterwards, sensors left behind relayed information about the concentration of various gases to monitors on the surface. With ventilation cut off, combustible methane gas began to collect behind the seal as expected. As the hours passed, concentration levels build steadily. At levels of between 5% and 15% the methane would be in the explosive range, after which it would become inert and stable. However, after only twenty-two hours, as the methane entered the explosive range, it came into contact with a heat source sufficiently intense to ignite it.

The people of Moura, a small company town several hundred miles northwest of Brisbane, were deeply shaken by the tragedy and the story led in the Australian media for several days. The questions most frequently asked were: Why did management allow normal underground operations to continue while such danger was present? Why did they fail to prevent the heating from occurring in the first place, to recognise the symptoms or to do something about it? The subsequent enquiry, which lasted 40 days, revealed numerous instances of inadequate monitoring and evaluation in an organisation that otherwise appeared to be well-managed in accordance with the applicable mining regulations. The official investigator, Frank Windridge (1996: 28) concluded that decision- making was marked by:

“less than adequate knowledge about spontaneous combustion … less than a desirable application of what knowledge there was; …failure to maintain communication and reporting systems; and lost opportunities through less than adequate responses to information available.”

In his estimation, the management group suspected heating was underway, but either did not realise that it was well advanced, or was unable to evaluate the implications. But Windridge left his strongest condemnation for the failure of management to withdraw the miners, especially the Sunday night shift when methane in the sealed paned was known to be approaching the explosive range. This, he said, represented ‘a passage of management neglect and non-decision which must never be repeated in the coal mining industry’ (Windridge, 1996: 41).

The management team

All mining operations in the Moura region were run by BHP Australia. In the period leading up to the disaster, maintaining production and profits had been difficult. As operations penetrated further underground it was hard to keep up a good return on investment, and stoppages ordered by the union or did not help. Management at Head Office in Brisbane was concerned and had relayed this to Moura. Here, the management staff included:

- Robert Regan, general manager: overall responsibility for the entire Moura site

- Albert Schaus, registered mine manager for Moura No. 2. A relative newcomer to the region (the rest of the management team had worked there for many years).

- George Mason, the under manager in charge and Schaus’ immediate subordinate: Mason had been under manager at Moura No. 4 in 1986 at the time of the explosion in that mine and had been fortunate in leaving the pit just half an hour before it happened. A strong, decisive manager with little time for his boss.

- Michael Squires, shift under manager, and Mason’s subordinate. On-site for most of the fateful weekend, with line responsibility for the shift deputies on duty. He was in the site office on the surface watching the gas screen monitors at the time of the explosion and had been there most of the day. He was on duty years before when a sudden and exponential increase in carbon monoxide indicated the danger of an imminent explosion, which, on that occasion, was fortunately diverted.

- Joe Barraclough, safety/training under manager

- Jacques Abrahamse, mine engineer

- Tony Morrison, ventilation and fire officer.

- McCamley, Klease, Robertson, Bryon, Newton and Caddell, shift deputies with key roles. They took charge of three shifts: day, afternoon and night.

Detecting a coal mine heating

The Moura coal seam was soft and gassy, and liable to spontaneous combustion due to its high methane gas content. To reduce the dangers, some of the methane was pre-drained from each panel before coal extraction commenced, and ventilation was used to remove heat and dangerous gasses. The idea was that even if the methane started to accumulate in a part of the goaf, there would be no hot coal there as a source of ignition – as long as the space was well ventilated.

Miners could detect a heating in progress through two means. First, there were sensory indicators including smells, hazes, vapour and heat. Because of the volume or air circulating through the mine, these could be fleeting or variable. Second, technical instruments were available to test for the presence of certain gases. Of these carbon monoxide (CO) was the most important as it is produced when coal burns. At Moura, gas samples were automatically collected from points in the mine, analysed, and reported on monitoring systems at ground level. Instruments measured both the quantity of air flowing through (air velocity) and its quality (concentrations of various gases). If a preset level of CO was breached, visual and auditory alarms would sound and the computer screen would change colour.

Management staff underground could also take instant readings of CO in parts per million (ppm) with their portable gas readers. Prior to the 1980s, CO concentration in ppm was the recommended indicator that a heating might be in progress. This was later revised in the standard text reference to ‘CO make’ (volume of gas in litres per minute, or lpm, taking both CO concentration and air velocity into account). Levels above 10 lpm were reckoned to be a cause for concern, while 20 lpm indicated that a heating was likely. To estimate CO make, the miner needed to take the reading on his portable monitor and make some calculations taking air velocity into account. This was practicable only when back on the surface.

Technical instruments available at Moura were advanced for the industry. But at the official inquiry, it became apparent that each person using them had different knowledge and ideas about the significance of various readings.

Not everyone was aware that CO make was the new standard, or knew how to calculate it. Opinions differed as to the level of CO that represented a danger, regardless of whether it was measured in ppm or lpm. Mason only learned how to calculate it on July 22 (when Abrahamse showed him), but he knew nothing of the 10 and 20 lpm thresholds. Squires knew that CO was important, but considered it a problem only if the level rose quickly. Only Abrahamse and Regan had any grasp of the most up to date technical opinions.

Worst of all, communication was such that management staff members were unaware of how divergent their views actually were. The extent of this was only revealed later.

“He entered the goaf and was shocked by what he found: warm air, a heat shimmy and a smell. Nothing had prepared him for this!”

Extraction of coal progresses

Extraction (the retreat phase) began in April and by mid-June parts of the mine were tiger country where floors were uneven and roof falls could occur without warning. The air at one time whistled by while at another, it slowed to a slight breeze. Splits in the ribs and stooks creaked and groaned. On Friday 17 June, shift deputy Robertson made his way into the mine on his regular inspection, noting a slightly elevated level of CO on his portable monitor. He immediately suspended production and phoned Mason who sent McCamley down, at that time the shift undermanager.

McCamley noticed the goaf felt warm and stuffy and was disturbed by what seemed to be a slight tar smell. Others later remembered that they noticed it too -one miner said it was a musty odour while someone else described it as a toiletry smell. Moriesen, the ventilation officer arrived and advised moving the brattices to get the air moving. He told the others that the smell was probably from the chemical roof bolts. In the back of his mind he had thoughts about a possible heating in the early stages and later discussed it with Abrahamse, the engineer. They agreed it could be the start of something but that they would be out before anything had time to develop. At the end of the shift McCamley made a comment to Mason and Squires who were in the office, but didn’t put anything in his shift report, one of his last before moving on to another mining job at the end of that month. Moriesen monitored the area from time to time before he went on leave in mid July, but found it difficult to reach the back of the mine because of roof falls. Knowing that the incubation period still had a few months to run, he thought nothing more of it.

The following Friday, shift deputy Reece Robertson was near a rough area used to throw waste and grease drums. There was a strong benzene type smell, he was quite sure. He took a reading on his portable monitor, read off a level of 7ppm and didn’t like it. Concerned, he phoned Michael Squires in the site office and asked him to keep an eye on it over the weekend. Later he made a note of the smell in his shift report. In the confusion of the Friday evening exodus and the arrival of the first-weekend shift, the report was buried under a pile of paperwork and did not reemerge until after the explosion six weeks later. At around the same time as Robertson was writing his report, a few of the men were talking about smells that seemed a bit unusual, but no one wanted to talk about heating. There were a few jokes about the time a few years back when Reece raised the alarm over a benzene smell when it turned out to be a toilet.

Moura mine disaster – One month later CO make trends

By mid-June, the average CO make was trending above 10 Ipm on the monitoring system in the site office above ground. By mid-July it had reached about 15 Ipm. On 22 July the relieving ventilation officer, Bryon, took a spot reading underground.

He was worried when it showed 8 ppm, as he was expecting around 6 ppm. When Abrahamse converted this figure to CO make, he was shocked to find that it came to 19 lpm, considerably higher than the weekly average. This could indicate the start of a heating. He sent another deputy underground to take a second reading and this time the level of CO was lower, corresponding to a CO make of about 13.7 lpm. Had the inexperienced Bryon been mistaken? Was there something wrong with the instruments? Was this reading an anomaly? By this time Mason had been advised. Abrahamse explained that he wanted to increase the level of monitoring by taking two readings daily, using two different instruments. Mason assumed that Abrahamse was doing this to check on the accuracy of the instruments and thought it a good idea, as they would find out if they needed recalibrating. Abrahamse also showed him how to calculate CO make. Mason found this interesting – he had heard of CO make, but had not really come across it before. Abrahamse drew up some charts for the deputies to use when recording the data, and showed one how to calculate CO make and asked that he report to him daily. Mason was happy to issue the necessary directives to deputies.

What followed were several days of intense data collection and recording. The shift deputies were content to go along with it although they didn’t know why it was necessary. They even increased the frequency of readings from once daily to every shift without being asked. One made a ritual of popping his head into the office every morning and announcing the latest CO reading to Barraclough, who was acting mine manager in the absence of Schaus. Barraclough found it all a little unnecessary if slightly amusing – as far as he was concerned, when it came to spontaneous combustion, there was nothing more significant than a haze or smell, and nothing like this had been reported.

For the next few days, CO levels remained about the same. Then Abrahamse went on sick leave five days later, and in his absence monitoring activity returned to normal. Barraclough was satisfied that the readings were not changing and took no further interest. He did not mention these events in his briefing to Schaus on his return from leave on 2 August. Nor did Mason or any of the others follow up, as they thought it was a waste of time. By then, however, the idea that background levels of CO were naturally high at Moura No. 2 had taken hold.

“Windridge left his strongest condemnation for the failure of management to withdraw the miners, especially the Sunday night shift when methane in the sealed paned was known to be approaching the explosive range.”

Over the next week CO make levels ranged between about 16 and 21 lpm. But with Abrahamse on sick leave levels were not calculated daily because no one was paying attention. Then, on Tuesday 2 August the visual and auditory alarms connected to the gas monitors at ground level automatically activated – the average level of CO over the day had registered at 7 ppm, the level preset to sound the alarms, for the first time. Someone, it was never discovered whom, deactivated the auditory alarm and reset the threshold to 8 ppm. Only the visual alarm remained – this registered as a change of screen colour on the monitor from green to red. The visual alarm activated again when 8 ppm CO was registered on the Wednesday, Friday and Saturday, and almost continuously after the panel was sealed. Several managers, including Squires, observed this phenomenon with little apparent concern.

Squires knew about CO make, it was the modern way of tracking CO, and he knew what to look for: an exponential rise in the level over a short period of time. He had been a technical assistant during a near miss from spontaneous combustion in the North West section of the mine in 1986. There, the CO had been slowly creeping up. Suddenly one morning it jumped from 13 to 23, and then just shot to 40 and then 80. From that experience, he knew you had to look out for when the reading changes and goes exponential.

FRIDAY 5 AUGUST

On Friday afternoon, 5 August at about 3 pm, a relieving deputy Mick Caddell began his inspection of the panel with another miner. Squires had told him to check for an increase in CO over previous shifts. Caddell’s first reading was 8 ppm, and a bit further along near the waste, he noticed a strong tar smell. His companion detected a similar thing. The CO reading there was 10 ppm. Caddell had a concern that something might be going on in the goaf – it reminded him of the burning smell after the explosion at Moura No. 4. How could he ever forget it? He phoned Squires with his report. Better to seal the panel as soon as possible, he told Squires, rather than wait till Sunday when it was planned. Squires said he would talk to Mason but to keep an eye on it in the meantime.

A few hours later when above ground Caddell mentioned the situation to Newton, the incoming shift supervisor. He also wrote his observations in his shift report and handed it to Squires. Squires knew Caddell well -he’d been a member of his shift many times and was a union rep. But he saw Caddell as inexperienced – he wasn’t familiar with panel 512 or the smells from the grease drums. If he was really concerned he would have been jumping up and down like he did when talking union business – Caddell wasn’t afraid of undermanagers and was not beyond a bit of yelling and gesticulation to draw their attention to matters that worried him. But just to be sure, Squires entered the mine and walked some way into the panel, noticing that the air was migrating towards the waste. Feeling a little uneasy about this he spoke to Mason when he arrived at the mine a bit later on, suggesting that they bring the sealing forward. Mason replied that he could see no reason to do so. Later that afternoon, Mason and Caddell left the mine.

SATURDAY 6 AUGUST

Squires entered the mine the next morning for the Saturday day shift – missing both overnight deputies on their way out. As he peered into the gloom he noticed a musty smell, a slight haze and a slow movement of air out of the waste. This was odd, because the air had been drifting in from a different direction the day before. Probably just a combination of dust and diesel fumes from machinery and the preparations being made around the seals. Still, it was as well to be prepared in case something started to happen quickly as it did before in the North West section. He phoned Klease the day shift deputy and asked him to do an inspection right away.

Shifts didn’t overlap on the weekends to save staffing costs, so unless the new shift came in early, they missed the earlier one by about 30 minutes. The incoming deputies read the previous shift reports, but usually not the ones before that. That morning Klease read the overnight shift reports, but did not see Caddell’s comments about a strong tar smell from the Friday afternoon, two shifts earlier. He entered the goaf and was shocked by what he found: warm air, a heat shimmy and a smell. Nothing had prepared him for this! He phoned Squires immediately with his report while the latter was on the other phone to Mason.

Mason wanted to know the CO reading and Squires passed it on – between 8 and 9 ppm. Righto, we’ll seal this afternoon, Mason said in response to another request from Squires, and hung up. Squires was a bit relieved by the CO reading since it had only risen slightly. But Klease, because of the smell, had a gut feeling that the situation was more serious than the readings were telling us. He was relieved when the sealing started early – if there was anything in there, there would be no more air going in to feed it.

Shortly after, Mason left his home, collected Parker, the sealing contractor, and drove him to the mine. He explained what was happening on the way. Parker later died in the explosion, but had noted in his diary: George Mason requested 1 pm that I go in because of concern overheating. Parker and his crew started work as soon as they arrived.

At the start of the Saturday afternoon shift, a few miners gathered around Squires for an informal meeting in the marshalling area. He told them about the change of plan – the early sealing was a precautionary measure due to the smells and other signs. Mason was there too. When the miners left for their work stations Mason went over to where the shift reports were kept and found two recent readings of CO recorded by the shift deputies.

He selected the lowest one and used it to calculate CO make. The level was 19 lpm. He was looking for evidence that there was no trend upwards over the previous shifts, something to give me comfort as he later put it. He was a bit relieved not to find an increase (the 10 and 20 lpm standards didn’t mean anything to him). So far everything seemed OK but he wanted to see the goaf for himself. He went in and met up with two deputies. One had earlier ventured to the spot where Caddell had detected the tar smell the day before and had found nothing unusual. By the time Mason arrived they were unable to proceed very far due to debris and roof falls, but he felt he had seen enough. There was no evidence of smells or hazes. Mason and the deputies all agreed that there was no problem – bringing forward the sealing had been unnecessary. He phoned Schaus at home, relayed the circumstances around the decision to seal early – he had gone along with Squires but it was overkill. Mason left the mine shortly after and did not return.

“Not everyone was aware that CO make was the new standard, or knew how to calculate it.”

SUNDAY 7 AUGUST

Squires, tired after many days of long shifts, returned to the mine the next morning at 6.30. By then the sealing was finished and the monitoring equipment was in place behind the solid concrete and brick walls that closed off panel 512 from the rest of the mine. He phoned Mason at home then went down to check the seals. Back in the site office he raised diagrams to monitor the atmosphere in the panel. He looked at them many times during the morning and early afternoon, and showed any miners who seemed interested. He phoned Mason again to report that the CO increase behind the seals appeared to be linear with no signs of exponential increase. Mason related his inspection of the previous afternoon and that nothing had caused him concern. Schaus called by at about 2.30 pm and entered a note in the record book of his inspection the previous Friday: 512 Panel … CO readings climbing steadily (8 ppm @ 19 lpm … Section will be sealed as soon as possible. Squires told him that the CO continued to rise steadily at around 6 ppm every hour: just as he expected. The explosive range for methane would be reached during the night shift.

After Schaus left Squires reminded himself that the decision to seal early was about ventilation and not a possible heating. The air simply wasn’t circulating properly and there was little point in mucking around with it any longer. Meanwhile, the monitors in front of him continued to flash red, as they had done all day. He didn’t notice any more, but kept a close eye on the steady rise of CO and the trend line for methane as it approached the explosive range.

The night shift of the Moura mine disaster

The mining regulations did not require work to stop during and after the sealing of panels. The pattern at Moura No. 2 was that work continued as normal. However, some of the men remembered an earlier time when it was standard practice to stay on the surface for a few clays until the methane gas became inert. In those clays, to prevent disruption to coal production, the sealing was usually done on a Friday night so that the clanger period fell during the weekend when production usually ceased anyway. Although that practice had fallen into abeyance (no explosions had occurred after a sealing), there was a view among the men that if the situation was dangerous, then management would tell them and work would stop. On August 7, the fact that shifts were still going underground, as usual, was proof enough that it must have been safe to do so.

The management group, for their part, was concerned that the men might refuse to work underground while panel 512 went through the explosive range. While Schaus was there earlier that afternoon Squires asked him what he should do if anyone on the night shift had concerns about entering the mine. In reply, Schaus said that you could not force anyone clown. He was to phone himself or Mason if the men raised any issues.

In a phone conversation with Mason around 7pm Squires asked a similar question. Should he call a meeting at the start of the night shift and give them a run clown of what had happened? Mason echoed what Schaus had said: It was not necessary. If the men or their deputies have any concerns they will raise it with you – there is quite a good grapevine about events in the mine, and they would know what was going on. If they refused to go clown, Squires should make a point of going into the mine himself.

Squires had a break at home during the afternoon and returned around 7.30 pm. He had another look at the diagrams. The trends remained steady. He thought about what he’d have to do if work underground was suspended: organise training sessions – the men hated them! Nine hours of going over the latest from some academic engineer with little or no experience of mining, and even less knowledge of the conditions at Moura!

After assembly, two night crews departed at about 10.20 pm in mine transports with Newton leading one group to the area around panel 512. The explosion occurred a little over an hour later, and Newton and most of his crew were lost.

Ultimately, there had been no decision on the part of mine management about having the miners remain out of the mine or not. Only Squires had raised concerns. As Windridge later wrote (Windridge, 1994: 41): It is regrettable that the air of caution, arising out of uncertainty, which was exhibited at the mine in order to bring forward the sealing … did not extend to the general safety and welfare of the workforce … to informing and keeping persons out of the mine for a time subsequent to that sealing. “Not everyone was aware that CO make was the new standard, or knew how to calculate it.”

A sad state when miners can’t be guaranteed they will come out of the mine alive.

They had outbursts of gas in that section as far back as mid eighties. If there was outburst they just moved the crew to another area!! The problem you had, in hindsite was that they were isolated, had worked the mine the wrongway from the start and had mined out all the coal on the way in . They didnt go as far as they could and work back they went in and pulled pillers on way in. It was only supposed to be a three year mine but ended up being mined for 20 years . I found the training to be non existent and people in positions making decisioins at the bowls club!! When I left in 1988I was pleased to have my back side still in one piece. Many of them didnt!!