The Queensland Coal Mines Inspector safety bulletin has released two incidents regarding coal mine workers (CMW) have fallen through a mesh walkway and a mesh platform. In both incidents the coal mine workers required medical treatment, however, the potential existed for injuries to have been far more serious.

Report into the serious injury of a worker at Appin North Mine

Emergency at Moura – What did we learn?

According to the report, one incident occurred on 27 January 2021, a coal mine workers was walking on a coal handling and preparation plant (CHPP) conveyor walkway. The section of steel mesh walkway the worker was on failed and fell through. The worker was able to lower himself to the ground through the open section of flooring using the handrails and adjacent steel structure for support. The worker was exposed to a potential fall of approximately two metres. The failed walkway and potential fall height are evident in the re-enactment shown in Figure 1.

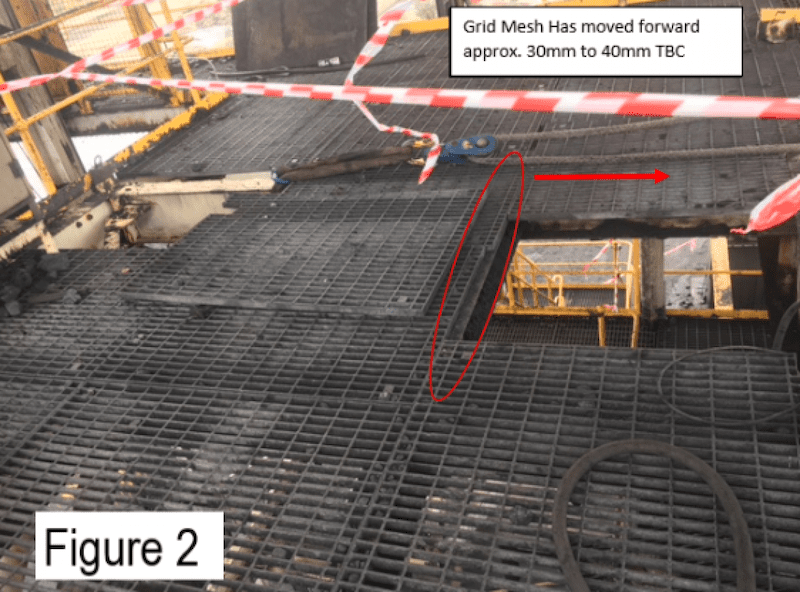

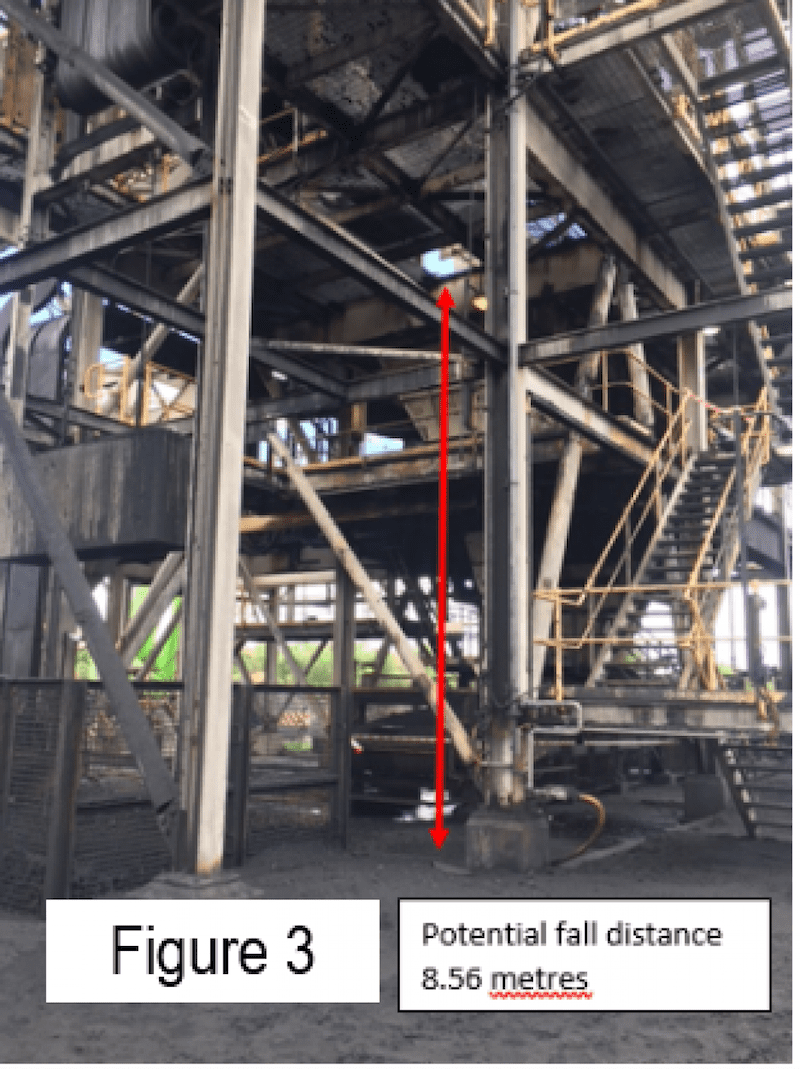

In the other incident, on 4 February 2021, a worker fell through a section of steel mesh floor. At the time of the incident, a roller screen in a CHPP tertiary crushing station was being pulled back into position. The worker walked behind the work area and fell through a section of floor mesh that wasn’t secured. The displaced mesh floor is shown in Figure 2. The worker was able to stop the fall with his arms, however, he potentially could have fallen 8.6 metres as depicted in Figure 3.

Both incidents are still being investigated, however the following is known:

- In the first incident the dislodged mesh panel was found to be heavily rusted (refer Figure 4) and the panel failed when the worker stood on it.

- In the second incident rigging being used to pull the roller screen appears to have dislodged one panel which then dislodged a second panel due to side loading imposed on the panels (refer Figure 2).

Other recent incidents

- In January 2018, a CMW stood on a piece of mesh floor adjacent to a crusher. The mesh panel fell from under his feet exposing the worker to a potential fall of approximately three metres.

- In July 2019, a CMW fell approximately 11 metres to the ground and suffered serious injuries when a section of mesh floor he was standing on failed. The injured CMW was located by his buddy after he failed to respond to a radio call.

- On 20 January 2021, a directive was issued by an Inspector of Mines, to a mine, to rectify multiple defects observed with CHPP mesh flooring. Defects included poorly fitted mesh panels, broken and distorted panel frames, and rusted through mesh bars.

Key issues to be addressed by the Site Senior Executive

- Ineffective inspections of walkways and platforms.

- Inspections of walkways and platforms not embedded in the work management system.

- Inadequate structural assessment and audit by the third party qualified engineers, with corrective actions not actioned in a timely manner.

- Housekeeping standards not maintained.

- Inadequate training and competency of persons conducting inspections.

- Mesh floor retention devices not suitable for environments subject to vibrations.

- Work not able to be completed as designed. Management of change processes not followed.

- Mesh retention devices are typically not designed to take horizontal loadings potentially leading to dislodgement of mesh panels.

Site Senior Executive to ensure that:

- At a minimum, designs for mesh floors and walkways meet or exceed requirements detailed in Australian Standard AS1657.

- Designs are suitable for the operating environment. This includes consideration of plant vibration and corrosive environments.

- Robust management of change processes are followed for design changes or changes in work methods.

- Operational loads imposed on mesh floor panels are in accordance with design assumptions.

- Structural integrity management plans include detailed inspections and checks by competent persons.

- Issues identified in structural integrity audits are acted upon in a risk based, timely manner.

- Inspection frequencies are reviewed to ensure a safe work environment is maintained between when a defect is identified, and remedial action is undertaken.

- Persons conducting regular inspections have been appropriately trained and assessed as competent to complete inspections.

- Embed inspections in Safety and Health Management System.

Read more Mining Safety News

Add Comment