An incident investigation report has been released by the NSW Mine Safety Regulator following the failure of a RUD link being used in a towing set up to tow an AFC Chain with a longwall shearer. The incident resulted in serious leg injuries to a mineworker after he was hit in the leg with a bow shackle on the failure of the RUD Link.

According to the regulator workers had established a towing system.

“Before the incident, the worker and co-workers were unjamming an armoured face conveyor (AFC) chain at the longwall. The AFC chain had a flight bar jammed in the bottom race. The jammed flight bar was released and the AFC chain required inspection to assess the damage. To help the inspection, workers decided to run the AFC in reverse and move the chain onto the top race. The tailgate slow runner drive on the AFC was not operational at the time. The maingate slow runner drive was not capable of moving the AFC chain. Workers decided to use the shearer (the longwall cutting machine) to support the maingate slow runner drive to move the AFC chain in reverse by towing the AFC chain with the shearer towards the tailgate end.”

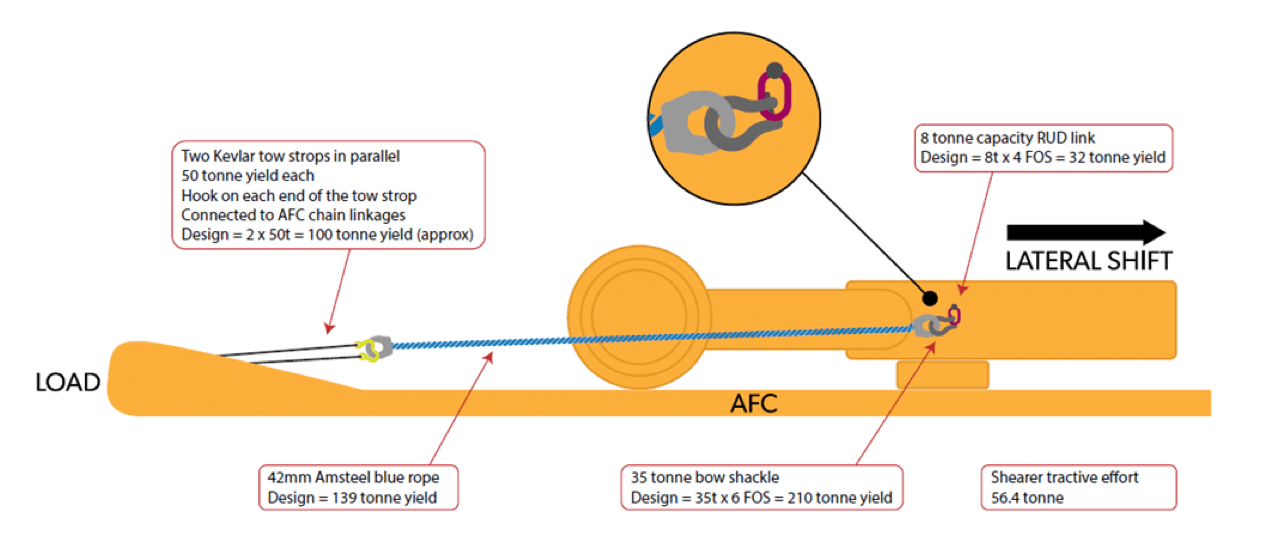

“Workers began to assemble a towing system to move the AFC chain using the shearer. The towing system consisted of a 35-tonne bow shackle, a 42-millimetre nylon rope and two ‘Recover Fast’ Kevlar 50-tonne tow strops fitted with 16-tonne coupling links and 16-tonne sling hooks at either end. The towing system was attached to the AFC chain, with the sling hooks of the tow straps hooked into the links of the AFC chain. The towing system was attached to the shearer using the 35-tonne bow shackle connected to an 8-tonne RUD link, which was fitted to the shearer.”

Significant Incident – Worker struck in head by high pressure airline

“The workers began to move the AFC chain by simultaneously powering the maingate slow runner and the shearer. Shortly after starting, a loud bang was heard. The 8-tonne RUD link on the shearer failed, resulting in the nylon rope with the 35-tonne bow shackle attached recoiling towards the maingate. The shackle hit the worker operating the shearer in the lower leg. The impact fractured his tibia and fibula.”

Other workers went to help the injured worker. He was given first aid before being transported to the surface. The injured worker was taken to hospital for treatment.

The Regulator said that the the direct cause of the incident was:

- the failure of the 8-tonne RUD link on the shearer, which was used as a connection point of the towing system, resulting in the uncontrolled release of energy.

It confirmed the following factors contributed to the incident:

- The RUD link attachment point was not fit-for-purpose.

- The working load limits of the towing system assembly were not known or assessed.

- Safe standing zones were not properly identified.

- No safe work procedure existed for the task and no job safety analysis (JSA) or risk assessment was undertaken.

- The workers were not trained in underground lifting, slinging and towing operations.

- The workers were not provided with adequate instruction, information or supervision while undertaking the task.

Images NSW Resources Regulator

Read more Mining Safety News

Add Comment