The Internet of Things and the Future of Mining Safety

Innovations in technology are dramatically changing the face of safety.

The expanding connectivity between people and devices has been a significant driver behind this rapid growth in modernisation. As we embrace this trend in our personal lives, organisations are also utilising technology through the ‘Internet of Things’ (IoT) to improve productivity and lower costs.

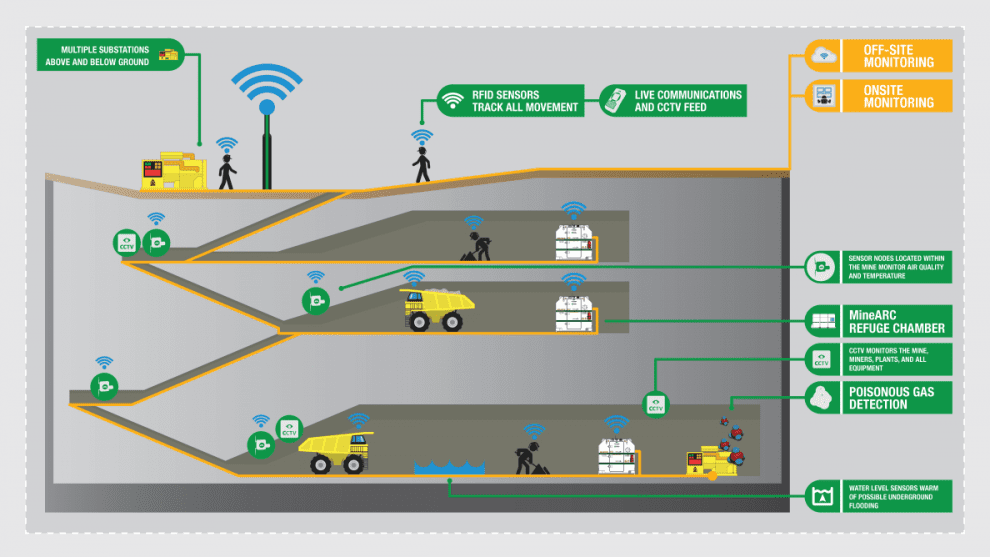

IoT has the potential to dramatically impact global safety standards by improving data relay and communications, across a robust underground network.

The Foundation of Connectivity

In basic terms, the concept of IoT is about connecting all ‘things’ to the internet and each other. ‘Things’ applies to all kinds of devices and their components such as a vibration sensor on a pump, telemetry from hardware sensors on a truck, light or motion sensors in crib rooms, RFID tracking or personnel tracking in a cap lamp.

Creating an Underground Network

As mine sites become digitalised, the need to collect and analyse more data increases, as does the number of devices linked to a network. The internet is usually something that’s easy to access, e.g. LTE connection in our pocket or Wi-Fi throughout the home; all allow a physical connection to a communications network. In an underground environment, this can often be challenging.

With the age of remote operations upon us, we need to address the challenges of connectivity underground through the implementation of a node network. Refuge chambers are ideally positioned to be an integral part of an underground communication network.

Local Refuge Chamber Node Network (LRCNN)

A refuge chamber supports a mixture of physical and radio communication links to IoT devices. Additionally, each chamber has a number of nodes connected to it creating a Local Refuge Chamber Node Network (LRCNN), which in turn connects to a broader network.

A MineARC node system, with refuge chambers at their hub, has been designed so that each subnetwork can become a local standalone network in the event of a catastrophic failure or disconnection through mining activities.

Local networks are crucial to monitoring events and environmental conditions to ensure the safety of all personnel and efficient re-entry procedures, through:

- Sensor reporting back to the refuge chambers.

- Monitoring atmospheric conditions such as gas levels, heat, dust and pressure within the LRCNN.

- First entry personnel can wait within the safe environments.

- Tracking of personnel allowing for accountability and efficient rescue operations, if required.

The expansion of MineARC’s products and developments, all part of the System Intelligence range, focuses on allowing other control systems to operate from information collected at the local refuge chamber node network.

GuardIAN Remote Monitoring and Diagnostics – Connecting Technology with the Workforce

More data than ever before is being received and analysed as the number of connected devices increases; however, information obtained must be decipherable and functional to the end user.

MineARC Systems have developed the platform GuardIAN to become the human interface for refuge chambers. Currently, GuardIAN is a real-time remote monitoring and diagnostics tool, reading from the life support systems through to the control room. It will expand to include an array of linked devices located anywhere with a broader network connection. Push notifications and data for a mine site, will effectively and efficiently solve problems and reduce the need for additional personnel to be underground.

The adoption of these new technologies will overcome common problems many organisations deal with on a daily basis when it comes to safety planning. Streamlining operational procedures through connected assets and data transfer will improve safety and regulatory compliance, and provide peace of mind that personnel are accounted for at any given time.

MineARC is pushing the limits of safety standards by embracing digital transformation incorporating IoT and product development. For further information about MineARC’s System Intelligence and to keep up to date as we launch our new products, visit http://minearc.com/systemintelligence/ or contact systemintelligence@minearc.com

Add Comment