The Queensland Mining Safety Regulator has advised of a serious incident that resulted in a mineworker being airlifted to a Brisbane hospital with a range of serious injuries.

The report documents have highlighted that there was no pressure control system in the piston or rod end chamber to control pressure intensification in the track press and that such a device could have reduced the rod end chamber pressure from the pump unit, and eliminated the intensification.

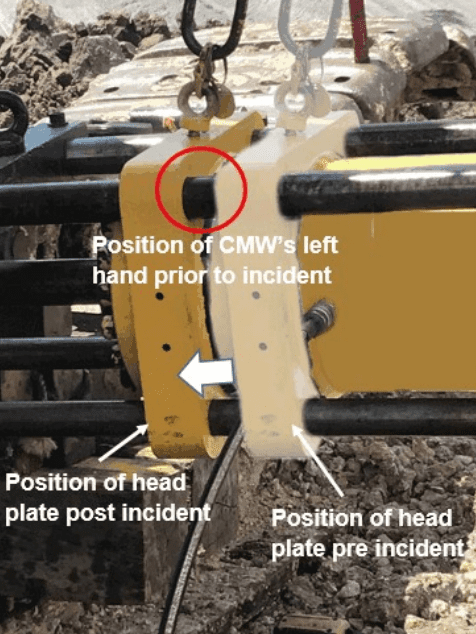

The Regulator’s report said “A serious accident occurred whilst coal mine workers (CMWs) were undertaking track repairs on a

Hitachi EX1900 excavator at a mine site (refer Figure 1). The workers were preparing to use a 360-tonne track press. Whilst aligning the track press in preparation to press out a track pin the pressurised cylinder head plate failed catastrophically. The failed component struck a worker causing serious arm injuries. He was airlifted to a Brisbane hospital and has required multiple operations and ongoing rehabilitation.”

READ RELATED

- QRC welcomes Brady Review into Mining Safety

- Safety Alert: Working with High Pressure Hydraulic Hoses

- Maintainer killed by relief valve while jacking shovel

Causes of the serious incident

According to available information, the Queensland mining safety regulator conducted an extensive investigation into the incident and identified a range of engineering factors that contributed to the cause of the incident. These included:

- Evidence of historic repeated occurrences of cylinder hydraulic pressure intensification.

- The head plate separated from the cylinder at the head plate weld. Repeated occurrences of pressure intensification in the rod end chamber i.e. overloading, initially caused cylinder distortion and ultimately head plate weld separation (refer Figure 2).

- Restricted oil flow from the rod end chamber, during normal pressing operations, created pressure intensification in a portion of the cylinder that is not supposed to experience high pressure.

- Poor internal engineering design of the cylinder resulted in pressure intensification.

- Poorly functioning hydraulic fittings (quick connect couplings) on the return hose restricted the oil flow, creating the high pressure condition in the rod end chamber.

- Inadequate deactivation of the quick connect check valves during operation resulted in a blocked hydraulic return line.

- Lack of appropriate pressure controls to prevent over-pressure events.

While the circumstances of the incident is unique, there has been a range of incidents over many years involving track assemblies. In 2002 while a dozer track master link assembly was being pressed together in the field using a portable hydraulic press, a spacer pin between the hydraulic press and the master link pin was ejected from the assembly at high speed striking the press operator breaking his leg.

IMAGES: Resources Safety & Health Queensland (Via information release)

Read more Mining Safety News

Add Comment